Archive:New Draft of the Week: Difference between revisions

imported>Daniel Mietchen m (→References) |

imported>Milton Beychok m (Prepared Wrench (tool) as Featured Article Candidate) |

||

| Line 18: | Line 18: | ||

| created = 2009-05-22 | | created = 2009-05-22 | ||

| score = 4 | | score = 4 | ||

}} | |||

{{Featured Article Candidate | |||

| article = Wrench (tool) | |||

| supporters = | |||

| specialists = [[User:Howard C. Berkowitz|Howard C. Berkowitz]] | |||

| created = 2009-05-31 | |||

| score = 3 | |||

}} | }} | ||

| Line 26: | Line 34: | ||

| <!-- dates --> 12 May 2009<br />11 June 2009 | | <!-- dates --> 12 May 2009<br />11 June 2009 | ||

| <!-- score --> 4 | | <!-- score --> 4 | ||

|- | |- | ||

Revision as of 23:36, 7 June 2009

The New Draft of the Week is a chance to highlight a recently created Citizendium article that has just started down the road of becoming a Citizendium masterpiece.

It is chosen each week by vote in a manner similar to that of its sister project, the Article of the Week.

Current Nominees

The next New Draft of the Week will be the article with the most votes at 1 AM UTC on Thursday, 11 June 2009. I did the honors this time. Milton Beychok 07:06, 5 June 2009 (UTC)

| Nominated article | Supporters | Specialist supporters | Dates | Score | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

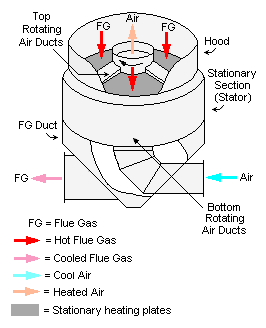

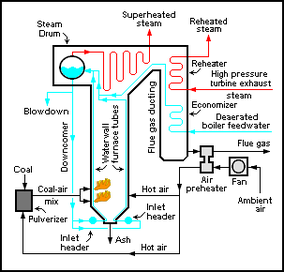

(PD) Image: Milton Beychok Schematic diagram of a steam generator in a conventional coal-fired power plant. An air preheater (APH) is a general term to describe any device designed to preheat the combustion air used in a fuel-burning furnace for the purpose of increasing the thermal efficiency of the furnace. In particular, this article describes the combustion air preheaters for the large fuel-burning furnaces used to generate steam in thermal power plants. The air preheater increases the steam generator's thermal efficiency by preheating the combustion air with heat recovered from the hot combustion flue gases (see the adjacent diagram). TypesThe two most often used categories of air preheaters in thermal power plants are regenerative air preheaters and tubular air preheaters.[1][2][3][4] Regenerative air preheatersThe two most common types of regenerative air preheaters are

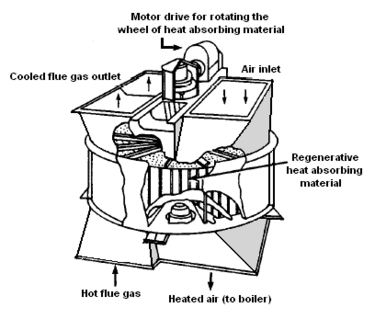

Regenerative air preheaters may also be categorized as recuperators, which are special types of heat exchangers designed to recover or reclaim heat in order to reuse or recycle it. Rotating-plate regenerative air preheater (PD) Image: U.S. Environmental Protection Agency A typical rotating-plate regenerative air preheater.[2]  (PD) Image: U.S. Environmental Protection Agency A typical rotating-plate regenerative air preheater.[2]

In the tri-sector design, the steam generator's hot flue gas flows through the largest sector (usually spanning about half the cross-section of the casing) and transfers some of its heat into the heat-absorbing material within the rotating wheel element. The cooled flue gas is then routed to further treatment in dust removal and other equipment before being vented from the flue gas stack. Ambient air is blown through the second, smaller sector by a centrifugal fan and absorbs heat from the heated material as it rotates through that smaller sector. The heated air then flows into the steam generating furnace as combustion air. The third sector is the smallest one and it heats a portion of the ambient air which is then routed into the coal pulverizations and is used to transport the coal-air mixture to coal burners. Thus, the total air heated in the RAPH provides: heated primary combustion air, heated air to remove moisture from the pulverized coal and carrier air for transporting the pulverized coal to the coal burners. Since the flue gas pressure is lower than the pressure of the air being heated, there is some small leakage (between the sectors) of flue gas into the air. The bi-sector design is used in thermal power plants burning fuels (such as oil or gas) that do not require pulverizing or removal of moisture and therefore have need for heated air other than for combustion air. The quad-sector design has a large sector heated by flue gas and three air-heating sectors: one is for the combustion air and that sector is flanked by two smaller air sectors. In applications such as circulating fluid bed (CFB) combustion systems where the differential between the air pressure and the flue gas pressure is even higher than in a conventional coal-fired steam generator, flue gas pressure, such a design is ideal since it acts to reduce the leakage of air into the flue gas.[6] The rotating wheel element rotates quite slowly (around 3-5 revolutions per minute) to allow optimum heat transfer first from the hot exhaust gases to the element and then, as it rotates, from the element to the air in the other sectors. Construction featuresThe heat-absorbing material in the rotating wheel element consists of vertical corrugated plates pressed into steel baskets, with sufficient space between the plates for the flue gas to pass through. The plates are corrugated to provide more surface area for the heat to be absorbed and also to provide needed rigidity. The baskets are designed to be replaceable as needed. The vertical shaft that rotates the wheel is supported on thrust bearings at the lower end lubricated with an oil bath that is cooled by water circulating in coils inside the oil bath. Cooling of the bottom end of the shaft is needed since that is where the hot flue gas enters the preheater. The top end of the shaft has a simple roller bearing to hold the shaft in a vertical position. Radial supports and cages for holding the corrugated plate baskets in position are attached to the rotating shaft. Radial and circumferential seal plates are also provided to minimize leakage of flue gas or air between the sectors. For cleaning of the baskets while in operation, steam jets are provided to blow any fly ash (deposited by the flue gas) into an ash hopper below the preheater. The rotating shaft is driven by a motor and gearing. To avoid uneven thermal expansion and contraction resulting in damage to the rotating wheel, the rotation must be started before starting the steam generator and must also be kept in rotation for some time after the steam generator is shut down. The baskets of corrugated plates are subject to abrasive and corrosive wear from the fly ash and corrosive gases in the flue gas. Hence frequent replacements are required and new baskets are always kept on hand and ready for use. Stationary-plate regenerative air preheaterThe heat absorbing element in this type of regenerative air preheater is stationary rather than rotating. Instead, the air ducts in the preheater are rotated so as to alternately expose sections of the heating absorbing element to the upflowing air. The hot flue gas enters at the top of the preheater and flows down through those exposed sections of the stationary heat-absorbing element that are not blocked by the rotating air outlet ducts, thus heating those sections of the stationary element. As the air ducts slowly rotate around, they pass over the heated sections and the incoming air is heated as it flows upward through those heated sections. As indicated in the adjacent drawing, there are rotating inlet air ducts (inside the outer casing) at the bottom of the stationary heat absorbing element as well as the rotating outlet air ducts at the top of the stationary element. The basic heat transfer principals of the stationary-plate regenerative preheater are the same as for the rotating-plate regenerative preheater. The table below provides a comparison of some design parameters between the rotating-plate and stationary-plate preheaters:

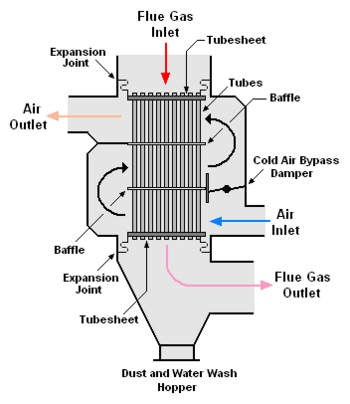

Tubular typeTubular air preheaters may have a number of configurations:[2][8][9]

A number of new circulating fluid bed (CFB) and bubbling fluid bed (BFB) steam generators are using tubular air preheaters, which avoids the air leakage associated with regenerative air preheaters. Dew point corrosionThe water dew point of air or any other gas containing water vapor usually refers to the temperature (for a given pressure) at which the air or gas is saturated with water vapor. That means that the air or gas is at the point where the water vapor will start to condense into liquid water if the temperature is lowered beyond that point. As a broad generality, the combustion flue gases from steam generators fueled by coal, fuel oil, natural gas, or biomass are composed of carbon dioxide (CO2) and water vapor (H2O) as well as nitrogen and excess oxygen remaining from the intake combustion air. Typically, more than two-thirds of the flue gas is nitrogen. The combustion flue gases may also contain small percentages of air pollutants such as particulate matter, carbon monoxide, nitrogen oxides, and sulfur oxides in the form of gaseous sulfur dioxide (SO2) and gaseous sulfur trioxide (SO3). The SO3 is present because a portion of the SO2 formed in the combustion of the sulfur compounds in the steam generator's furnace fuel is further oxidized to SO3 as the flue gas travels through the superheater and reheater sections of the steam generator (see the above diagram of a steam generator). The gas phase SO3 then combines the vapor phase H2O to form gas phase sulfuric acid H2SO4:[10]

Because of the presence of gaseous sulfuric acid, the dew point of most flue gases is much higher than the water dew point of air and the flue gas dew point is referred to as the acid dew point. That is the flue gas temperature at which acid will begin to condense out of the flue gas if the temperature is lowered beyond that point. For example, a flue gas with 5 volume % water vapor and containing no acid gases has a water dew point of about 32 °C (90 °F). The same flue gas with the addition of only 0.01 volume percent of SO3 will have an acid dew point of about 118 °C (244 °F).[11] The acid dew point of a combustion flue gas depends upon the composition of the specific fuel being burned and the resultant composition of the flue gas. Given a flue gas composition, its acid dew point can be predicted fairly closely. As an approximation, the acid dew points of flue gases from thermal power plants range from about 120 °C to about 150 °C (250 to 300 °F). All of the air preheater types incur erosion problems to some extent from the fly ash particles in the flue gas. If the hot flue gas temperature in an air preheater is lowered to below its acid dew point, then the air preheater also incurs corrosion problems which can be quite severe. That is especially true of the tubular air preheaters. For that reason, many air preheaters have a means for the air to partially bypass the air preheater (see above tubular air preheater diagram) so that the amount of heat exchange can be controlled to avoid lowering the flue gas temperature below the acid dew point. To mitigate dew point corrosion, the tubular air preheaters may use ceramic or Teflon-coated tubes and the regenerative air preheaters may use special corrosion-resistant steels or enameled materials. The addition of limestone (CaCO3) into circulating fluidized bed (CFB) steam generators results in capturing 95% or more of the gaseous SO2 in the combustion product gases as solid calcium sulfate (Ca2SO4) and that occurs before the SO2 has time to be further oxidized to SO3. Thus, the acid dew point of the flue gas from a CFB steam generator is higher than from conventional thermal power plant steam generators. That means that the air preheaters in CFB units have considerably less dew point corrosion problems. That may also be one of the reasons why a number of the newer CFB units are using tubular preheaters. References

|

Daniel Mietchen | Milton Beychok | 4

| |||||||||||||||||||||||

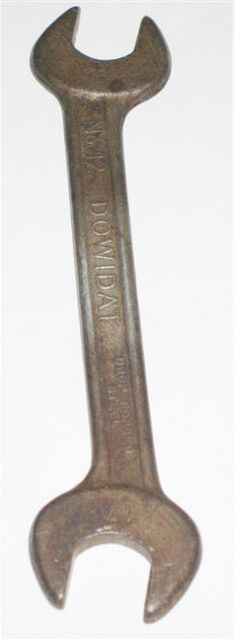

A wrench (American English), or spanner (British English), is a fastening tool used to manipulate threaded fasteners such as nuts, studs and bolts. They also may manipulate threaded structural elements such as pipes. The wrench is sized and shaped to put pressure and leverage on flat faces of the fastener, and then is moved in the direction of rotation needed to loosen or tighten the fastening assembly. Hand toolsThe most common hand wrenches are made either from a flat bar of steel, or from cylinders. Even with these two types, the wrench can either completely or partially surround the fastener. Flat BarThe most common hand wrenches either are open-ended, such that they have sides parallel to two or more facets of the nut, or box, which surrounds all sides of the nut. These types can drop over the nut no matter how much of the screw or bolt protrudes. The longer the handle of the wrench, the more force can be applied to the fastener. One technique is to carry a length of pipe, which can slip over the wrench and act as a handle extender. Do be warned, however, that a sufficiently long pipe can exert enough force to break the wrench or the fastener. Still, there are times when it is absolutely necessary to release a stuck fastener. It is usually wise first to apply a penetrating lubricant to the fastener, and tap it gently to let the lubricant reach the threads, waiting briefly before applying force. Yet another dangerous but sometimes necessary technique is to hit the handle of the wrench with a hammer; do remember to hit it in the direction in which the fastener needs to turn. Gloves and eye protection are wise precautions when hammering a wrench. An even more desperate expedient is to heat the fastener to expand it, which may destroy the hardness or toughness of the metal. Occasionally, it is possible to chill the piece to which the fastener is attached, contracting it and helping break the adhesion. For some specialized applications, typically where only authorized persons are to adjust the fastener, the sides of the wrench head may not be parallel. For example, the nuts on fire hydrants are pentagonal, so they cannot be manipulated with a standard wrench shape. Combination wrenchA combination wrench has a one open and one box end, usually of the same size. The open end is more useful when there is limited access to the fastener. Box ends can get a better grip when the flats of the nut are deformed.Adjustable open wrenchAn adjustable wrench has one fixed jaw, and one that is adjustable by means of a screw adjustment, usually made in one piece with the adjustable jaw. In the U.S., this is often called a Crescent wrench after the first well-known manufacturer, while it is a Bahco wrench in Dutch usage, after the Swedish manufacturer. The obvious advantage of the adjustable wrench is that an entire set of wrenches need not be carried when the size of the fastener to be adjusted is not known. The disadvantage is that the adjustment can slip, and generally cannot apply as much force as a solid wrench. It should be mentioned, if mostly to condemn the practice, that pliers are sometimes used to adjust nuts. Most types of pliers, however, do not have parallel jaws, but angled ones. These are apt to deform a nut if heavy pressure is applied. Pipe wrenchPipe wrenches grasp threaded pipes and turn them, so they do not have flat jaws. One common type has curved jaws, with the wrench designed to slip slightly so it can be repositioned as the pipe moves under it. These were called Stillson wrenches after the inventor; they are sometimes, incorrectly, called monkey wrenches. Another type does not have jaws, but instead a chain that tensions against the pipe. Some plumbing fixtures have a nut-like shape molded into the metal, so that a flat-jawed wrench can be used. This is the application intended for the increasingly rare monkey wrench. Socket wrenches and nutdriversSockets proper are single pieces of cast or machined metal, with one end shaped to slip over the fastener to be manipulated, and the other to receive a driveshaft to turn it. The shaft end may actually have a depression, or even a spring-loaded bearing, to help lock the shaft into place. In combination, the driveshaft and socket are extremely strong in rotation, but should separate easily with linear traction. Where the English measurement system is used, the shaft diameter is most often 3/8" or 1/4" for general purposes. 1/2", 3/4", and 1" drives are used for heavy equipment. Both metric and English system sockets, however, can snap onto the male end of the shaft. Adapters are available to convert between shaft sizes. For example, one might have a large nut but only a 1/4" shaft system, so an adapter can allow a 3/8" socket to be used with that shaft. Basic handle and extensionThe most basic driver is a shaft with a handle, much like a screwdriver, but with a socket-mating connector rather than a screwdriver bit. Another very common variant, called an extension, has a male connector that mates with the socket at one end, and a female connector that accepts another socket tool at the other. Multiple extensions can be snapped together for extra length. NutdriversNutdrivers are a permanently attached set of socket, driveshaft, and handle. Some nutdrivers have hollow shafts, so bolt length protruding above the nut goes into the hollow and does not interfere with rotation. Aids to leverageMost often, however, at the end of the extension away from the socket, a tool to improve the leverage of driving is attached. One such tool is a ratchet, which, at first, looks like an open-ended or box wrench. The male connector, however, is attached to a disk and mechanical components inside the ratchet head. There is a small control that selects the direction (i.e., loosening or tightening) in which the socket is to be moved. Once that control is set, the ratchet moves freely in the other direction, so it can be repositioned easily; it is not necessary to have 360 degree access above the fastener -- just enough working space to move the ratchet handle. Other ways to improve leverage include various pivoting handles. One type looks like the brace (tool) used to drive hand drills; there is a socket fitting rather than a chuck at the working end. The operator holds a knob, fitted with bearings in which the shaft turns, and cranks a handle. Another type, called a flex handle, is related to the rachet, but, rather than rotating, the handle pivots 180 degrees so it can be repositioned quickly. A flex handle is simpler, cheaper, and may be able to apply more force than a rachet. Torque wrenchesA torque wrench is both a fastening tool and a measuring device. It is used where precise measurement of the tightness of a bolt is necessary. It has been suggested that a quantum mechanical torque wrench can measure either the torque, or find the bolt, but not both. Spanners (precision)While a spanner is a general term in British English for "wrench", there is a specialized tool always known as a spanner. It consists of a bar with two or more protruding pins, sometimes adjustable in distance, that fit into corresponding holes in a fastener an allow it to be turned. The bar is connected to a shaft or other mechanism to allow turning, or sometimes the spanner is built not as a bar, but as a pliers-like device with the pins at the work end. Spanners are often used in optical work, on the retaining rings of lens elements. Power wrenchesImpact wrenchesOne of the most common types is a power-operated driver for sockets, the sockets usually made of extra-strong metal. Pneumatically driven impact wrenches are extremely common in the automotive industry; air drive does not generate the sparks that an electric motor could produce, which would be hazardous in the presence of petroleum products. For other applications, however, electric impact wrenches are increasingly common, especially cordless battery-powered wrenches with great portability. For some heavy applications, the impact energy may be provided by an explosive cartridge. There are impact wrenches that are hand-powered, but by hitting a specific part with a hammer, allowing great force to be applied. Power torque wrenchIntended for industrial applications, these are often powered hydraulically, which allows great precision. (Read more...) |

Howard C. Berkowitz | 3

| ||||||||||||||||||||||||

| Milton Beychok | Daniel Mietchen | 12 May 2009 11 June 2009 |

4 | |||||||||||||||||||||||

| Milton Beychok; Meg Ireland | 18 May 2009 19 June 2009 |

2 | ||||||||||||||||||||||||

| Daniel Mietchen; Meg Ireland | 11 May 2009 10 June 2009 |

2 | ||||||||||||||||||||||||

Current Winner

To change, click edit and follow the instructions, or see documentation at {{Featured Article}}.

| The metadata subpage is missing. You can start it via filling in this form or by following the instructions that come up after clicking on the [show] link to the right. | |||

|---|---|---|---|

|

The 2009 H1N1 influenza virus, commonly referred to as swine flu, is an influenza A virus first discovered in April 2009, which contains human, porcine and avian genes.[1] Those infected with the H1N1 virus report symptoms similar to those observed in most influenza A viral infections, namely fever, cough, sore throat, body aches, headache, chills and fatigue, and a significant fraction of those afflicted report diarrhea and vomiting. It may cause severe illness and death. Although seasonal influenza normally differentially affects certain populations, including young children, people over 65 years of age, pregnant women, and the chronically ill, population related risks are yet to be determined for this virus. The virus is contagious so common health care precautions should be taken to avoid contracting this flu.

Epidemiology

The 2009 H1N1 influenza virus is a novel H1N1 strain.[2] Although in the prior 2007-2008 season, H1N1 was about a third of all cases[3], starting in April 2009 a H1N1 strain emerged that was initially untypeable. The 2009 novel H1N1 influenza virus contains genes normally found in North American swine as well as two genes found in European and Asian swine and has been called a triple-reassortant of genes.[2][4]

Prevention

General good health practices should be taken to avoid this and other illnesses. Most importantly, wash your hands often, and avoid sick persons and unnecessarily touching surfaces. Stay fit by eating a well-balanced, nutritious diet, drink plenty of water, get sufficient sleep each day, and exercise. The use of antibacterial soaps are no better than regular soaps at removing this virus from your hands.

Once infected, one may reduce the spread of the flu in a number of simple ways.

Hygiene

- Do not cough or sneeze into your hands directly, but cover your nose and mouth with a tissue (or shirt sleeve - the current suggestion is, in the absence of a tissue, cough or sneeze into the crux of your elbow rather than your hands).

- Throw the tissue away directly, without setting it on other surfaces, such as desk tops or kitchen counters.

- Wash your hands often with soap and water, especially after you cough or sneeze.

- Avoid touching your eyes, nose or mouth, and wash your hands afterwards.

- Stay home for 7 days after symptoms begin or you have been symptom free for 24 hours.

- Avoid close contact with sick people.

- Avoid shopping after becoming ill. Buy at least a one week supply of medications, tissues, soaps, and so on.

Medications and Infectivity

The antiviral drugs oseltamivir and/or zanamivir are recommended by the Centers for Disease Control for the treatment and/or prevention of 2009 H1N1. These antiviral drugs inhibit the reproductive cycle of the virus, thereby ameliorating the severity and length of illness. Although the period of infectivity for a person with H1N1 has yet to be determined, persons with influenza are typically contagious beginning 1 day before the onset of symptoms and 7 days after symptom onset. Childrem may be contagious for a longer time period.

Food, Water and Recreation

One can not become infected by the swine flu from eating properly cooked pork products. Based on previous studies of the H5N1 avian flu, it is expected that chlorine levels used in municipal water supplies should be sufficient to kill the H1N1 virus. Likewise, properly treated water at swimming pools, spas, water parks, interactive fountains, and other treated recreational water venues should be free of the virus. The virus is contagious so common health care precautions should be taken to avoid contracting this flu.

Seeking Medical Attention

One should seek immediate medical attention when patients experience any of the following warning signs:

In Adults or Children:

- difficult or rapid breathing,

- Chest/Abdominal pain or pressure

- Sudden dizziness or confusion

- Severe or persistent vomiting

Additional warning signs in children:

- Bluish or gray skin color

- Insufficient fluid intact

- Not waking up or interacting

- Being so irritable that the child does not want to be held

- Flu-like symptoms improve but then return with fever and worse cough

- Fever with a rash

Treatment

Peramivir is an investigational intravenous neuraminidase inhibitor that can be used.[5]

Complications

Various pulmonary complications may occur including pulmonary embolism.[6]

References

- ↑ NCBI list of deposited sequences for 2009 H1N1

- ↑ 2.0 2.1 Novel Swine-Origin Influenza A (H1N1) Virus Investigation Team. Dawood FS, Jain S, Finelli L, Shaw MW, Lindstrom S et al. (2009). "Emergence of a novel swine-origin influenza A (H1N1) virus in humans.". N Engl J Med 360 (25): 2605-15. DOI:10.1056/NEJMoa0903810. PMID 19423869. Research Blogging.

- ↑ 2007-08 U.S. INFLUENZA SEASON SUMMARY, Centers for Disease Control and Prevention

- ↑ Swine Flu & You

- ↑ Birnkrant D, Cox E (2009). "The Emergency Use Authorization of Peramivir for Treatment of 2009 H1N1 Influenza.". N Engl J Med. DOI:10.1056/NEJMp0910479. PMID 19884645. Research Blogging.

- ↑ Agarwal PP et al (2009) Chest Radiographic and CT Findings in Novel Swine-Origin Influenza A (H1N1) Virus (S-OIV) Infection American Journal of Radiology

Previous Winners

Gasoline: A fuel for spark-ignited internal combustion engines derived from petroleum crude oil. [e] (21 May)

Gasoline: A fuel for spark-ignited internal combustion engines derived from petroleum crude oil. [e] (21 May) John Brock: Fictional British secret agent who starred in three 1960s thrillers by Desmond Skirrow. [e] (8 May)

John Brock: Fictional British secret agent who starred in three 1960s thrillers by Desmond Skirrow. [e] (8 May) McGuffey Readers: A set of highly influential school textbooks used in the 19th and early 20th centuries in the elementary grades in the United States. [e] (14 Apr)

McGuffey Readers: A set of highly influential school textbooks used in the 19th and early 20th centuries in the elementary grades in the United States. [e] (14 Apr) Vector rotation: Process of rotating one unit vector into a second unit vector. [e] (7 Apr)

Vector rotation: Process of rotating one unit vector into a second unit vector. [e] (7 Apr) Leptin: Hormone secreted by adipocytes that regulates appetite. [e] (31 Mar)

Leptin: Hormone secreted by adipocytes that regulates appetite. [e] (31 Mar) Kansas v. Crane: A 2002 decision of the Supreme Court of the United States, ruling that a person could not be adjudicated a sexual predator and put in indefinite medical confinement, purely on assessment of an emotional disorder, but such action required proof of a likelihood of uncontrollable impulse presenting a clear and present danger. [e] (24 Mar)

Kansas v. Crane: A 2002 decision of the Supreme Court of the United States, ruling that a person could not be adjudicated a sexual predator and put in indefinite medical confinement, purely on assessment of an emotional disorder, but such action required proof of a likelihood of uncontrollable impulse presenting a clear and present danger. [e] (24 Mar) Punch card: A term for cards used for storing information. Herman Hollerith is credited with the invention of the media for storing information from the United States Census of 1890. [e] (17 Mar)

Punch card: A term for cards used for storing information. Herman Hollerith is credited with the invention of the media for storing information from the United States Census of 1890. [e] (17 Mar) Jass–Belote card games: A group of trick-taking card games in which the Jack and Nine of trumps are the highest trumps. [e] (10 Mar)

Jass–Belote card games: A group of trick-taking card games in which the Jack and Nine of trumps are the highest trumps. [e] (10 Mar) Leptotes (orchid): A genus of orchids formed by nine small species that exist primarily in the dry jungles of South and Southeast Brazil. [e] (3 Mar)

Leptotes (orchid): A genus of orchids formed by nine small species that exist primarily in the dry jungles of South and Southeast Brazil. [e] (3 Mar) Worm (computers): A form of malware that can spread, among networked computers, without human interaction. [e] (24 Feb)

Worm (computers): A form of malware that can spread, among networked computers, without human interaction. [e] (24 Feb) Joseph Black: (1728 – 1799) Scottish physicist and chemist, known for his discoveries of latent heat, specific heat, and carbon dioxide [e] (11 Feb 2009)

Joseph Black: (1728 – 1799) Scottish physicist and chemist, known for his discoveries of latent heat, specific heat, and carbon dioxide [e] (11 Feb 2009) Sympathetic magic: The cultural concept that a symbol, or small aspect, of a more powerful entity can, as desired by the user, invoke or compel that entity [e] (17 Jan 2009)

Sympathetic magic: The cultural concept that a symbol, or small aspect, of a more powerful entity can, as desired by the user, invoke or compel that entity [e] (17 Jan 2009) Dien Bien Phu: Site in northern Vietnam of a 1954 decisive battle that soon forced France to relinquish control of colonial Indochina. [e] (25 Dec)

Dien Bien Phu: Site in northern Vietnam of a 1954 decisive battle that soon forced France to relinquish control of colonial Indochina. [e] (25 Dec) Blade Runner: 1982 science fiction film directed by Ridley Scott and starring Harrison Ford, set in an imagined Los Angeles of 2019. [e] (25 Nov)

Blade Runner: 1982 science fiction film directed by Ridley Scott and starring Harrison Ford, set in an imagined Los Angeles of 2019. [e] (25 Nov) Piquet: A two-handed card game played with 32 cards that originated in France around 1500. [e] (18 Nov)

Piquet: A two-handed card game played with 32 cards that originated in France around 1500. [e] (18 Nov) Crash of 2008: the international banking crisis that followed the subprime mortgage crisis of 2007. [e] (23 Oct)

Crash of 2008: the international banking crisis that followed the subprime mortgage crisis of 2007. [e] (23 Oct) Information Management: The application of management principles to the acquisition, organization, control, dissemination and use of information relevant to the effective operation of organizations of all kinds. [e] (31 Aug)

Information Management: The application of management principles to the acquisition, organization, control, dissemination and use of information relevant to the effective operation of organizations of all kinds. [e] (31 Aug) Battle of Gettysburg: A turning point in the American Civil War, July 1-3, 1863, on the outskirts of Gettysburg, Pennsylvania. [e] (8 July)

Battle of Gettysburg: A turning point in the American Civil War, July 1-3, 1863, on the outskirts of Gettysburg, Pennsylvania. [e] (8 July) Drugs banned from the Olympics: Substances prohibited for use by athletes prior to, and during competing in the Olympics. [e] (1 July)

Drugs banned from the Olympics: Substances prohibited for use by athletes prior to, and during competing in the Olympics. [e] (1 July) Sea glass: Formed when broken pieces of glass from bottles, tableware, and other items that have been lost or discarded are worn down and rounded by tumbling in the waves along the shores of oceans and large lakes. [e] (24 June)

Sea glass: Formed when broken pieces of glass from bottles, tableware, and other items that have been lost or discarded are worn down and rounded by tumbling in the waves along the shores of oceans and large lakes. [e] (24 June) Dazed and Confused (Led Zeppelin song): Landmark 1969 song recorded by Led Zeppelin for their eponymous debut album, which became an early centrepiece for the group's live performances. [e] (17 June)

Dazed and Confused (Led Zeppelin song): Landmark 1969 song recorded by Led Zeppelin for their eponymous debut album, which became an early centrepiece for the group's live performances. [e] (17 June) Hirohito: The 124th and longest-reigning Emperor of Japan, 1926-89. [e] (10 June)

Hirohito: The 124th and longest-reigning Emperor of Japan, 1926-89. [e] (10 June) Henry Kissinger: (1923—) American academic, diplomat, and simultaneously Assistant to the President for National Security Affairs and Secretary of State in the Nixon Administration; promoted realism (foreign policy) and détente with China and the Soviet Union; shared 1973 Nobel Peace Prize for ending the Vietnam War; Director, Atlantic Council [e] (3 June)

Henry Kissinger: (1923—) American academic, diplomat, and simultaneously Assistant to the President for National Security Affairs and Secretary of State in the Nixon Administration; promoted realism (foreign policy) and détente with China and the Soviet Union; shared 1973 Nobel Peace Prize for ending the Vietnam War; Director, Atlantic Council [e] (3 June) Palatalization: An umbrella term for several processes of assimilation in phonetics and phonology, by which the articulation of a consonant is changed under the influence of a preceding or following front vowel or a palatal or palatalized consonant. [e] (27 May)

Palatalization: An umbrella term for several processes of assimilation in phonetics and phonology, by which the articulation of a consonant is changed under the influence of a preceding or following front vowel or a palatal or palatalized consonant. [e] (27 May) Intelligence on the Korean War: The collection and analysis, primarily by the United States with South Korean help, of information that predicted the 1950 invasion of South Korea, and the plans and capabilities of the enemy once the war had started [e] (20 May)

Intelligence on the Korean War: The collection and analysis, primarily by the United States with South Korean help, of information that predicted the 1950 invasion of South Korea, and the plans and capabilities of the enemy once the war had started [e] (20 May) Trinity United Church of Christ, Chicago: A predominantly black church located in south Chicago with upwards of 10,000 members, established in 1961. [e] (13 May)

Trinity United Church of Christ, Chicago: A predominantly black church located in south Chicago with upwards of 10,000 members, established in 1961. [e] (13 May) BIOS: Part of many modern computers responsible for basic functions such as controlling the keyboard or booting up an operating system. [e] (6 May)

BIOS: Part of many modern computers responsible for basic functions such as controlling the keyboard or booting up an operating system. [e] (6 May) Miniature Fox Terrier: A small Australian vermin-routing terrier, developed from 19th Century Fox Terriers and Fox Terrier types. [e] (23 April)

Miniature Fox Terrier: A small Australian vermin-routing terrier, developed from 19th Century Fox Terriers and Fox Terrier types. [e] (23 April) Joseph II: (1741–1790), Holy Roman Emperor and ruler of the Hapsburg (Austrian) territories who was the arch-embodiment of the Enlightenment spirit of the later 18th-century reforming monarchs. [e] (15 Apr)

Joseph II: (1741–1790), Holy Roman Emperor and ruler of the Hapsburg (Austrian) territories who was the arch-embodiment of the Enlightenment spirit of the later 18th-century reforming monarchs. [e] (15 Apr) British and American English: A comparison between these two language variants in terms of vocabulary, spelling and pronunciation. [e] (7 Apr)

British and American English: A comparison between these two language variants in terms of vocabulary, spelling and pronunciation. [e] (7 Apr) Count Rumford: (1753–1814) An American born soldier, statesman, scientist, inventor and social reformer. [e] (1 April)

Count Rumford: (1753–1814) An American born soldier, statesman, scientist, inventor and social reformer. [e] (1 April) Whale meat: The edible flesh of various species of whale. [e] (25 March)

Whale meat: The edible flesh of various species of whale. [e] (25 March) Naval guns: Artillery weapons on ships, and techniques and devices for aiming them. [e] (18 March)

Naval guns: Artillery weapons on ships, and techniques and devices for aiming them. [e] (18 March) Sri Lanka: An island nation in South Asia, located 31 km off the south-east coast of India, formerly known as Ceylon . [e] (11 March)

Sri Lanka: An island nation in South Asia, located 31 km off the south-east coast of India, formerly known as Ceylon . [e] (11 March) Led Zeppelin: English hard rock and blues group formed in 1968, known for their albums and stage shows. [e] (4 March)

Led Zeppelin: English hard rock and blues group formed in 1968, known for their albums and stage shows. [e] (4 March) Martin Luther: German theologian and monk (1483-1546); led the Reformation; believed that salvation is granted on the basis of faith rather than deeds. [e] (20 February)

Martin Luther: German theologian and monk (1483-1546); led the Reformation; believed that salvation is granted on the basis of faith rather than deeds. [e] (20 February) Cosmology: A branch of astronomy and of metaphysics committed to the study of the universe as a whole, of the contents, structure, and evolution of the universe from the beginning of time to the future. [e] (4 February)

Cosmology: A branch of astronomy and of metaphysics committed to the study of the universe as a whole, of the contents, structure, and evolution of the universe from the beginning of time to the future. [e] (4 February) Ernest Rutherford: (August 30, 1871 - October 19, 1937)The first person to split an atom. [e](28 January)

Ernest Rutherford: (August 30, 1871 - October 19, 1937)The first person to split an atom. [e](28 January) Edinburgh: Add brief definition or description (21 January)

Edinburgh: Add brief definition or description (21 January) Russian Revolution of 1905: Add brief definition or description (8 January 2008)

Russian Revolution of 1905: Add brief definition or description (8 January 2008) Phosphorus: Add brief definition or description (31 December)

Phosphorus: Add brief definition or description (31 December) John Tyler: Add brief definition or description (6 December)

John Tyler: Add brief definition or description (6 December) Banana: Add brief definition or description (22 November)

Banana: Add brief definition or description (22 November) Augustin-Louis Cauchy: Add brief definition or description (15 November)

Augustin-Louis Cauchy: Add brief definition or description (15 November)- B-17: Add brief definition or description - 8 November 2007

Red Sea Urchin: Add brief definition or description - 1 November 2007

Red Sea Urchin: Add brief definition or description - 1 November 2007 Symphony: Add brief definition or description - 25 October 2007

Symphony: Add brief definition or description - 25 October 2007 Oxygen: Add brief definition or description - 18 October 2007

Oxygen: Add brief definition or description - 18 October 2007 Origins and architecture of the Taj Mahal: Add brief definition or description - 11 October 2007

Origins and architecture of the Taj Mahal: Add brief definition or description - 11 October 2007 Fossilization (palaeontology): Add brief definition or description - 4 October 2007

Fossilization (palaeontology): Add brief definition or description - 4 October 2007 Cradle of Humankind: Add brief definition or description - 27 September 2007

Cradle of Humankind: Add brief definition or description - 27 September 2007 John Adams: Add brief definition or description - 20 September 2007

John Adams: Add brief definition or description - 20 September 2007 Quakers: Add brief definition or description - 13 September 2007

Quakers: Add brief definition or description - 13 September 2007 Scarborough Castle: Add brief definition or description - 6 September 2007

Scarborough Castle: Add brief definition or description - 6 September 2007 Jane Addams: Add brief definition or description - 30 August 2007

Jane Addams: Add brief definition or description - 30 August 2007 Epidemiology: Add brief definition or description - 23 August 2007

Epidemiology: Add brief definition or description - 23 August 2007 Gay community: Add brief definition or description - 16 August 2007

Gay community: Add brief definition or description - 16 August 2007 Edward I: Add brief definition or description - 9 August 2007

Edward I: Add brief definition or description - 9 August 2007

Rules and Procedure

Rules

- The primary criterion of eligibility for a new draft is that it must have been created no more than one month before the date of the next selection (Currently every Thursday).

- Articles must be ranked 1 or 2 (developed or developing).

- Any Citizen may nominate a draft.

- No Citizen may have nominated more than one article listed under "current nominees" at a time.

- The article's nominator is indicated simply by the first name in the list of votes (see below).

- At least for now--while the project is still small--you may nominate and vote for drafts of which you are a main author.

- An article can be the New Draft of the Week only once. Nominated articles that have won this honor should be removed from the list and added to the list of previous winners.

- Comments on nominations should be made on the article's talk page.

- Any draft will be deleted when it is past its "last date eligible". Don't worry if this happens to your article; consider nominating it as the Article of the Week.

- If an editor believes that a nominee in his or her area of expertise is ineligible (perhaps due to obvious and embarrassing problems) he or she may remove the draft from consideration. The editor must indicate the reasons why he has done so on the nominated article's talk page.

Nomination

- Before nominating an article, you must make the changes listed at Template:Featured Article Candidate.

- Then, you can add the article to the list above using the {{Featured Article Candidate}} template.

- Add your article in the correct position in the list according to the rules below.

Voting

- To vote, add your name and date in the Supporters column next to an article title, after other supporters for that article, by signing <br />~~~~. (The date is necessary so that we can determine when the last vote was added.)

- Add your name in the Specialist supporters column only if you are an editor who is an expert about the topic in question. Your vote will be counted as three.

- You may vote for as many articles as you wish, and each vote counts separately, but you can only nominate one at a time; see above. You could, theoretically, vote for every nominated article on the page, but this would be pointless.

Ranking

- The list of articles is sorted by number of votes first, then alphabetically.

- Admins should make sure that the votes are correctly tallied, but anyone may do this. Note that "Specialist Votes" are worth 3 points.

Updating

- Each Thursday, one of the admins listed below should move the winning article to the Current Winner section of this page, announce the winner on Citizendium-L and update the "previous winning drafts" section accordingly.

- The winning article will be the article at the top of the list (ie the one with the most votes).

- In the event of two or more having the same number of votes :

- The article with the most specialist supporters is used. Should this fail to produce a winner, the article appearing first by English alphabetical order is used.

- The remaining winning articles are guaranteed this position in the following weeks, again in alphabetical order. No further voting should take place on these, which remain at the top of the table with notices to that effect. Further nominations and voting take place to determine future winning articles for the following weeks.

- Winning articles may be named New Draft of the Week beyond their last eligible date if their circumstances are so described above.

- The article with the most specialist supporters is used. Should this fail to produce a winner, the article appearing first by English alphabetical order is used.

Administrators

The Administrators of this program are the same as the admins for CZ:Article of the Week.

References

See Also