User:Milton Beychok/Sandbox

Glycol dehydration is a chemical engineering unit process that uses a liquid desiccant, usually a glycol, for the removal of water from natural gas and natural gas liquids (NGL). It is the most common and economic means of water removal from these streams.[1][2]

The glycols typically used in dehydration process units include:

- ethylene glycol (MEG), formula = C2H6O2

- diethylene glycol (DEG), formula = C4H10O3

- triethylene glycol (TEG), formula = C6H14O4

- tetraethylene glycol (TTEG), formula = C8H18O5

Of the four glycols listed above, triethylene glycol (TEG) is the one most commonly used in dehydrating natural gas.

Purpose

The purpose of a glycol dehydration unit is to remove water from natural gas and natural gas liquids. When produced from an underground reservoir, raw natural gas is usually saturated with water vapor at the water (i.e., the gas is at its water dew point). Without dehydration, liquid water could condense out of the gas as it is either cooled or the pressure is lowered as the gas flows through [Natural gas processing|processing facilities]] and pipelines. This liquid water phase may contain some amount of acid gas, such as hydrogen sulfide (H2S) or carbon dioxide (CO2) and can cause corrosion.[1]

At low temperatures, methane hydrates (also known as methane clathrates) may form.[3] Depending on the natural gas composition, methane hydrates can form at relatively high temperatures and cause plugging of equipment and piping.[1] Drying the gas with glycol dehydration unit lowers the temperature at which hydrate formation will occur.

For the above reasons, pipeline quality specifications for natural gas usually mandate that the water content should not exceed 4 to 7 pounds per million SCF (68 to 118 mg per Nm3 ).[4] Glycol dehydration units must typically meet this specification at a minimum, although further removal may be required if additional hydrate formation temperature depression is required.

Process description

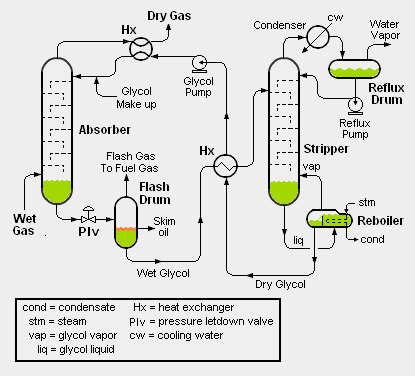

Lean, water-free glycol (purity >99%) is fed to the top of an absorber where it is contacted with the wet natural gas stream. The glycol removes water from the natural gas by physical absorption and is carried out the bottom of the column. Upon exiting the absorber the glycol stream is often referred to as "rich glycol". The dry natural gas leaves the top of the absorption column and is fed either to a pipeline system or to a gas plant. Glycol absorbers can be either tray columns or packed columns.

After leaving the absorber, the rich glycol is fed to a flash vessel where hydrocarbon vapors are removed and any liquid hydrocarbons are skimmed from the glycol. This step is necessary as the absorber is typically operated at high pressure and the pressure must be reduced before the regeneration step. Due to the composition of the rich glycol, a vapor phase having a high hydrocarbon content will form when the pressure is lowered.

After leaving the flash vessel, the rich glycol is heated in a cross-exchanger and fed to the stripper (also known as a regenerator). The glycol stripper consists of a column, an overhead condenser, and a reboiler. The glycol is thermally regenerated to remove excess water and regain the high glycol purity.

The hot, lean glycol is cooled by cross-exchange with rich glycol entering the stripper. It is then fed to a lean pump where its pressure is elevated to that of the glycol absorber. The lean solvent is cooled again with a trim cooler before being fed back into the absorber. This trim cooler can either be a cross-exchanger with the dry gas leaving the absorber or an aerial type cooler.

Other components

Wet gas knockout drum: Some glycol dehydration facilities include routing of the wet gas feedstock through a vapor-liquid separator drum (also referred to as a knockout drum) to remove any entrained liquid water droplets before entering the glycol unit absorber.

Glycol filter: Some glycol dehydration facilities include a filter within the circulating glycol system to remove any undesirable solid particles that could lead to plugging of the various equipment items.

Stripper top internal condenser: Instead of the external condenser, reflux drum and reflux pump shown in the above schematic flow diagram, some glycol units use a coil (through which a coolant stream flows) installed directly in the top of the stripper. The exit water vapor stream is then vented directly from the top of the stripper.

Other configurations

Most glycol units are fairly uniform except for the regeneration step. Several methods are used to enhance the performance of the the glycol stripper so as achieve lower levels of residual water vapor in the product dry gas from the absorber.

Since the reboiler temperature of the glycol stripper is limited to about 400 °F (about 200 °C) to prevent thermal degradation of the circulating glycol, many of the enhanced systems focus on lowering the partial pressure of water in the stripper to increase the removal of water from the wet glycol. Common enhancing methods include the use of stripping gas as well as reboil heat and lowering the total stripper pressure by using a vacuum system.

There are two proprietary process designs that are available:

The DRIZO process design: The DRIZO design also focuses on improving the stripping of water from the glycol bu using a recoverable hydrocarbon solvent instead of a stripping gas.

The Coldfinger process design: Where the vapors in the reboiler are partially condensed and drawn out separately from the bulk liquid.

References

- ↑ 1.0 1.1 1.2 Gas Processors Suppliers Association (GPSA) Handbook, Tenth Edition.

- ↑ Arthur L. Kohl and Fred C. Riesenfeld (1984). Gas Purification, 4th Edition. Gulf Publishing Co.. ISBN 0-87201-314-6.

- ↑ Hydrates or clathrates are crystalline water-based solids physically resembling ice, in which gas molecules are trapped inside "cages" of water molecules

- ↑ SCF = standard cubic feet of gas at 60 °F and 1 atm. Nm3 = normal cubic meters of gas at 0 °C and 1 atm. 1 Nm3 = 37.326 SCF.

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++ External links

- Gas Processors Suppliers Association Website

- Design Glycol Units for Maximum Efficiency Vincente N. Hernandez-Valencia, Michael W. Hlavinka and Jerry A. Bullin, Proceedings of the Seventy-First GPA Annual Convention, Tulsa, OK, 1992, pp 310-317. An excellent discussion on the design details of glycol units.

- Kh. Mohamadbeigy (2008). "Studying of the Effectiveness Parameters on Gas Dehydration Plant". Petroleum & Coal 50 (2): pp 47-51. ISSN 1337-7027.