User:Milton Beychok/Sandbox

Delayed coking is one of the chemical engineering unit processes used in many petroleum refineries. In brief, the process heats the residual oil from the crude oil distillation unit in a petroleum refinery to its thermal cracking temperature in the heat transfer tubes of a furnace. This cracks the long chain hydrocarbon molecules of the residual oil into coker gas oil and petroleum coke.[1][2][3].

Some delayed coking units produce as much as 5,000 tons of coke per day.[4]

Flow diagram and process description

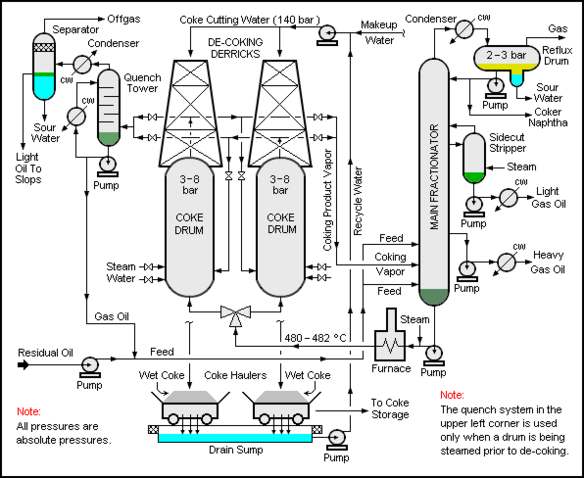

The diagram and description in this section are based on typical delayed coking unit with two coke drums. However, larger units have tandem pairs of drums, some with as many as 6 drums, each of which may have diameters of up to 10 meters and overall heights of up to 43 meters.[5]

Typical schematic flow diagram

Process description

Thermal cracking begins in the furnace line between the furnace and the coke drums and finishes in the coke drum that is on-stream.

As cracking continues in the drum, gas oil and lighter components are generated in vapor phase and separate from the liquid and solids. The drum effluent is vapor except for any liquid or solids entrainment, and is directed to a distillation column where it is separated into the desirable boiling point fractions. Solid coke is deposited in the drum in a porous structure that allows flow through the pores.

After the drum is full of the solidified coke, the hot mixture from the furnace is switched to the second drum. While the second drum is filling, the full drum is steamed out to further reduce the hydrocarbon content of the petroleum coke, and then quenched with water to cool it. The top and bottom heads of the full coke drum are removed, and the solid petroleum coke is then cut from the coke drum with a high pressure water nozzle, where it falls into a pit, pad, or sluiceway for reclamation to storage.

Composition of petroleum coke

The table below illustrates the wide range of specifications for raw petroleum coke (referred to as green coke[6]) produced in a delayed coker and the corresponding compositions after the green coke has been calcined at in a rotary kiln at 1200 to 1400 °C:

| Component | Green coke as produced |

Coke calcined at 2375 °F |

|---|---|---|

| Fixed carbon, wt % | 86 − 92 | 99.5 |

| Sulfur, wt % | <2.5 | <2.5 |

| Volatile matter, wt % | 8− 14 | 0.5 |

| Moisture, wt % | 6-14 | 0.1 |

| Ash, wt % | 0.25 | 0.4 |

| Iron | 0.01 | 0.02 |

| Nickel | 0.02 | 0.03 |

| Silicon | 0.02 | 0.02 |

| Vanadium | 0.02 | 0.03 |

History

Petroleum coke was first made in the 1860's in the early oil refineries in Pennsylvania which boiled oil in small, iron distillation stills to recover kerosene, a much needed lamp oil. The stills were heated by wood or coal fires built underneath them, which over-heated and coked the oil near the bottom. After the distillation was completed, the still was allowed to cool and workmen could then dig out the coke and tar.[8]

In 1913, William Merriam Burton, working as a chemist for the Standard Oil of Indiana refinery at Whiting, Indiana, was granted a patent[9] for the Burton thermal cracking process that he had developed.

References

- ↑ Gary, J.H. and Handwerk, G.E. (1984). Petroleum Refining Technology and Economics, 2nd Edition. Marcel Dekker, Inc. ISBN 0-8247-7150-8.

- ↑ Leffler, W.L. (1985). Petroleum refining for the nontechnical person, 2nd Edition. PennWell Books. ISBN 0-87814-280-0.

- ↑ Petroleum Coke Glossary

- ↑ Staff (November 2002). "2002 Refining Processes". Hydrocarbon Processing: pp. 85-147. ISSN 0887-0284.

- ↑ Delayed coking innovations and new design trends

- ↑ Petroleum coke (from the IUPAC Compendium of Chemical Terminology

- ↑ David S.J. Jones and Peter P.Pujado (Editors) (2006). Handbook of Petroleum Processing, First Edition. Springer. ISBN 1-4020-2819-9. (page 61)

- ↑ Tutorial: Delayed Coking Fundamentals (written by Paul Ellis and Christopher Paul of the Great Lakes Carbon Corporation)

- ↑ United States Patent Number 0149667