API oil-water separator: Difference between revisions

Pat Palmer (talk | contribs) m (Text replacement - "Philadelphia" to "Philadelphia, Pennsylvania") |

mNo edit summary |

||

| (One intermediate revision by one other user not shown) | |||

| Line 17: | Line 17: | ||

==History== | ==History== | ||

The API separator was developed about 75 years ago by the API and the Rex Chain Belt Company. The first API separator was installed in 1933 at the Atlantic Refining Company (ARCO) refinery in [[Philadelphia, Pennsylvania]]. Since that time, virtually all of the refineries worldwide have installed API separators in their wastewater treatment plants. The majority of those refineries installed the API separators using the original design based on the specific gravity difference between oil and water. However, many refineries now use plastic parallel plate packing to enhance the gravity separation.<ref name=API421/><ref name=Aqueous/> | The API separator was developed about 75 years ago by the API and the Rex Chain Belt Company. The first API separator was installed in 1933 at the Atlantic Refining Company (ARCO) refinery in [[Philadelphia, Pennsylvania|Philadelphia]]. Since that time, virtually all of the refineries worldwide have installed API separators in their wastewater treatment plants. The majority of those refineries installed the API separators using the original design based on the specific gravity difference between oil and water. However, many refineries now use plastic parallel plate packing to enhance the gravity separation.<ref name=API421/><ref name=Aqueous/> | ||

==Other oil-water separation applications== | ==Other oil-water separation applications== | ||

| Line 29: | Line 29: | ||

==References== | ==References== | ||

{{reflist}} | {{reflist}}[[Category:Suggestion Bot Tag]] | ||

Latest revision as of 11:01, 4 July 2024

An API oil-water separator is a device designed to separate gross amounts of oil and suspended solids from the wastewater effluents of petroleum refineries, petrochemical and chemical plants, natural gas processing plants and other industrial sources.

The name is derived from the fact that such separators are designed according to standards published by the American Petroleum Institute (API). [1][2]

Description of the design and operation

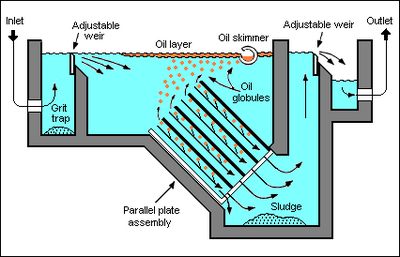

The API separator is a gravity separation device designed by using Stokes' Law to define the rise velocity of oil droplets based on their density and size. The design of the separator is based on the density difference between the oil and the wastewater because that difference is much smaller than the specific gravity difference between the suspended solids and water. Based on that design criterion: most of the suspended solids will settle to the bottom of the separator as a sediment layer, the oil will rise to top of the separator and the wastewater will be the middle layer between the water on top and the solids on the bottom.[2]

Typically, the oil layer is skimmed off and subsequently re-processed or disposed of, and the bottom sediment layer is removed by a chain and flight scraper (or similar device) and a sludge pump. The water layer is sent to further treatment consisting usually of a dissolved air flotation (DAF) unit for further removal of any residual oil and then to some type of biological treatment unit for removal of undesirable dissolved chemical compounds.

Parallel plate separators are similar to API separators but they include tilted parallel plate assemblies (also known as parallel packs).[2] The underside of each parallel plate provides more surface for suspended oil droplets to coalesce into larger globules. Any sediment slides down the topside of each parallel plate. Such separators still depend upon the specific gravity between the suspended oil and the water. However, the parallel plates enhance the degree of oil-water separation. The result is that a parallel plate separator requires significantly less space than a conventional API separator to achieve the same degree of separation.

History

The API separator was developed about 75 years ago by the API and the Rex Chain Belt Company. The first API separator was installed in 1933 at the Atlantic Refining Company (ARCO) refinery in Philadelphia. Since that time, virtually all of the refineries worldwide have installed API separators in their wastewater treatment plants. The majority of those refineries installed the API separators using the original design based on the specific gravity difference between oil and water. However, many refineries now use plastic parallel plate packing to enhance the gravity separation.[1][2]

Other oil-water separation applications

There are other applications requiring oil-water separation. For example:

- Oily water separators (OWS) for separating oil from the bilge water accumulated in ships as required by the international MARPOL Convention.[3][4]

- Oil and water separators are commonly used in electrical substations. The transformers found in substations use a large amount of oil for cooling purposes. Moats are constructed surrounding unenclosed substations to catch any leaked oil, but these will also catch rainwater. Oil and water separators provide a quick and easy cleanup of an oil leak.[5]

References

- ↑ 1.0 1.1 American Petroleum Institute (February 1990). Management of Water Discharges: Design and Operations of Oil-Water Separators, 1st Edition. American Petroleum Institute.

- ↑ 2.0 2.1 2.2 2.3 Beychok, Milton R. (1967). Aqueous Wastes from Petroleum and Petrochemical Plants, 1st Edition. John Wiley & Sons. LCCN 67019834.

- ↑ International Convention for the Prevention of Pollution from Ships, 1973 (and later amendments)., from the website of the International Maritime Organization (IMO).

- ↑ Oily water separator

- ↑ Leonard L.Grigsby (2001). The Electrical Power Engineering Handbook. CRC Press. ISBN 0-8493-8578-4.