ThorCon nuclear reactor: Difference between revisions

(→Cost: clarify refurbishment schedule) |

m (→Cost: clarify challenge in keeping cost down) |

||

| Line 51: | Line 51: | ||

'''Initial fuel load (2 cans):''' 78,000kg NaF-BeF2-ThF4-UF4 (76-12-10.2-1.8 mol %) | '''Initial fuel load (2 cans):''' 78,000kg NaF-BeF2-ThF4-UF4 (76-12-10.2-1.8 mol %) | ||

The main challenge in designing a molten salt reactor is the lifetime of components exposed to high temperature and high levels of neutron irradiation. Special steels were used in early reactor experiments<ref>[https://en.wikipedia.org/wiki/Molten-Salt_Reactor_Experiment#Structural_alloy_Hastelloy-N Hastelloy-N]</ref> to resist corrosion by the flowing molten salt. ThorCon uses standard type 316 stainless steel, and plans for complete refurbishment every eight years of all components in the can, including the pot, the pump, and the primary heat exchanger. After four years of service, each can is drained and left in its silo to "cool" for four more years, then returned to the factory. Thin steel in the heat exchanger is replaced with new. Thicker steel is annealed with a torch. After 8 refurbishments, the slightly radioactive steel is melted down and recycled for new reactors. | The main challenge in designing a low-cost molten salt reactor is the lifetime of components exposed to high temperature and high levels of neutron irradiation. Special steels were used in early reactor experiments<ref>[https://en.wikipedia.org/wiki/Molten-Salt_Reactor_Experiment#Structural_alloy_Hastelloy-N Hastelloy-N]</ref> to resist corrosion by the flowing molten salt. ThorCon uses standard type 316 stainless steel, and plans for complete refurbishment every eight years of all components in the can, including the pot, the pump, and the primary heat exchanger. After four years of service, each can is drained and left in its silo to "cool" for four more years, then returned to the factory. Thin steel in the heat exchanger is replaced with new. Thicker steel is annealed with a torch. After 8 refurbishments, the slightly radioactive steel is melted down and recycled for new reactors. | ||

Lifetime of the reactor is actually limited more by the graphite moderator than by degradation of the steel. The graphite is shaped into hexagonal logs 300mm flat to flat and 2.1m long. Holes are drilled lengthwise through the logs to allow salt to flow and remove heat deposited in the graphite. Neutron irradiation causes graphite to expand and contract and develop microcracks that allow salt intrusion and erosion of the flow channels. The expected lifetime is 3e22 n/cm2 for energies greater than 50keV at 680C. ThorCon’s graphite needs are similar to those of an HTGR (High Temperature Gas-cooled Reactor). The main difference is ThorCon needs a fine-grained graphite that will resist salt intrusion at reactor pressure (6 bar).<ref>[https://thorconpower.com/wp-content/uploads/2019/04/graf_spec_20190419.pdf ThorCon graphite specification]</ref> | Lifetime of the reactor is actually limited more by the graphite moderator than by degradation of the steel. The graphite is shaped into hexagonal logs 300mm flat to flat and 2.1m long. Holes are drilled lengthwise through the logs to allow salt to flow and remove heat deposited in the graphite. Neutron irradiation causes graphite to expand and contract and develop microcracks that allow salt intrusion and erosion of the flow channels. The expected lifetime is 3e22 n/cm2 for energies greater than 50keV at 680C. ThorCon’s graphite needs are similar to those of an HTGR (High Temperature Gas-cooled Reactor). The main difference is that ThorCon needs a fine-grained graphite that will resist salt intrusion at reactor pressure (6 bar).<ref>[https://thorconpower.com/wp-content/uploads/2019/04/graf_spec_20190419.pdf ThorCon graphite specification]</ref> | ||

== Notes and References == | == Notes and References == | ||

{{Reflist|2}} | {{Reflist|2}} | ||

Revision as of 21:41, 18 April 2022

- See also: Nuclear_power_reconsidered

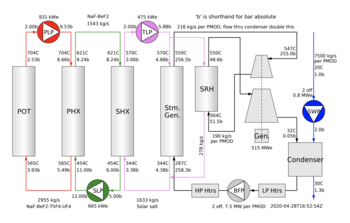

ThorCon power train. An extra heat exchange loop ensures no leakage of radiation. Overall efficiency still above 46%.[2]

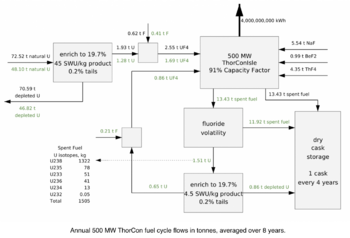

Raw material flows and waste at a ThorCon fuel processing plant. Enriched uranium powers the cycle, but most of the energy comes from the more abundant thorium.[3]

Thorcon nuclear reactors are molten salt reactors with a graphite moderator. These reactors (and the entire power plant) are to be manufactured on an assembly line in a shipyard, and delivered via barge to any ocean or major waterway shoreline. The reactors are delivered as a sealed unit and never opened on site. All reactor maintenance and fuel processing is done at a secure location.

This article provides brief answers to the questions raised in Nuclear power reconsidered. For more details see the ThorCon documents[4] and ThorCon's Status Report to the IAEA.[5]

Safety

Accidental overheating. There are salt plugs at the bottom of the reactor vessel that melt if the reactor gets too hot, and allow the fuel to flow out of the reactor into drain tanks, where the fission reaction stops, and the decay heat is absorbed by a "cold wall".[6] There are no safety-critical systems or valves and no electronic or computer systems vulnerable to cyber attack.[7] No operator action is required, and there is nothing an operator can do to stop a safe shutdown. Reactors that meet these requirements are called "walk-away safe".

Leakage of Radioactivity The molten salt is at low pressure, and any leakage from the reactor will quickly solidify. The most troublesome fission products, including iodine-131, strontium-90 and cesium-137, are chemically bound to the salt. There is no pressurized water near the reactor vessel. Leakage to the environment is blocked by three gas-tight barriers - the Can, the Silo, and the Hull.[8] Tritium is captured by getters in inert gas in the power module hall and in the secondary heat exchanger cell. A third salt loop allows any tritium penetrating both heat exchangers to be captured in the third loop.[7] Xenon and krypton bubble out in the header tank, are held in storage tanks until they have decayed to harmless levels, and then cooled, compressed and stored.[9]

Sabotage The hull is a 10ft thick wall of sand with an inch of steel on each side, capable of blocking a jumbo jet with nine-ton engines.[7] Reactivity can be increased only by adding fuel slowly through an orifice inside the silo, out of reach of any rogue operator. The maximum rate of increase in reactivity is enough for load following, but never enough that the reactor can go prompt critical.[7] Should a group of terrorists seize control of the plant and attempt to remove fuelsalt, they would require use of the 500-ton deck crane, which could be easily disabled with small artillery.[10] There is no vulnerability to cyber attack.

Waste Management

The "waste" in the ThorCon fuel cycle is actually valuable fuel for future fast neutron reactors capable of efficiently burning thorium and depleted uranium. This will extend proven resources from centuries to millennia.

Average per year for a 500MW plant:[3]

High Level Waste: 13,400kg to dry-cask storage[11]

Medium and Low Level Waste: 343 tonnes of irradiated steel (one of the 4 "cans") shipped out for refurbishment.

Recycled Fuel: 650kg of 19.7% U-235 (33% of total U consumption)

Other: (Medical isotopes, etc.)

Weapons Proliferation

The reactors are delivered as sealed cans and never opened on site. All reactor maintenance and fuel processing is done at a central secure location.

There is no online chemical processing to remove fission products or anything else, and no highly enriched material anywhere — none above 20% U-235.

The sealed cans are inside a high-radiation silo under a heavy concrete lid. Any attempt to get inside the silo can be detected by sensors and security cameras and stopped by local police or military.

Uranium is always low-enriched. Plutonium is always diluted with thorium, in fuel salt with hazardous fission products.[7] Making bombs from this material will be far more difficult than starting from uranium ore.

Cost

ThorCon claims the expected cost of a complete power plant will be less than a coal plant of equal power.[12] Everything except the structure itself is replaceable. After four years of operation and four years of cooling, the sealed reactor can with the entire primary loop is returned to a centralized recycling facility, decontaminated, disassembled, inspected, and refurbished. Incipient problems are caught before they can turn into casualties. Thorcon plants with replaceable sealed reactors can operate for 80 years; but if a ThorCon is decommissioned, the process is little more than pulling out but not replacing all the replaceable parts.[13]

Specs for a 500MW plant:[7]

Plant cost per KW: $1200

Operating cost per KWh: $0.03 (including $0.006 for fuel)

Fuel consumption per day: 5.3kg of 19.7% enriched uranium plus 9.0kg of thorium.[3]

-145 tonnes of natural uranium per GW-year compared to about 250 tonnes for a standard light water reactor

- future re-enrichment of spent fuel will cut this uranium requirement by a third

Initial fuel load (2 cans): 78,000kg NaF-BeF2-ThF4-UF4 (76-12-10.2-1.8 mol %)

The main challenge in designing a low-cost molten salt reactor is the lifetime of components exposed to high temperature and high levels of neutron irradiation. Special steels were used in early reactor experiments[14] to resist corrosion by the flowing molten salt. ThorCon uses standard type 316 stainless steel, and plans for complete refurbishment every eight years of all components in the can, including the pot, the pump, and the primary heat exchanger. After four years of service, each can is drained and left in its silo to "cool" for four more years, then returned to the factory. Thin steel in the heat exchanger is replaced with new. Thicker steel is annealed with a torch. After 8 refurbishments, the slightly radioactive steel is melted down and recycled for new reactors.

Lifetime of the reactor is actually limited more by the graphite moderator than by degradation of the steel. The graphite is shaped into hexagonal logs 300mm flat to flat and 2.1m long. Holes are drilled lengthwise through the logs to allow salt to flow and remove heat deposited in the graphite. Neutron irradiation causes graphite to expand and contract and develop microcracks that allow salt intrusion and erosion of the flow channels. The expected lifetime is 3e22 n/cm2 for energies greater than 50keV at 680C. ThorCon’s graphite needs are similar to those of an HTGR (High Temperature Gas-cooled Reactor). The main difference is that ThorCon needs a fine-grained graphite that will resist salt intrusion at reactor pressure (6 bar).[15]

Notes and References

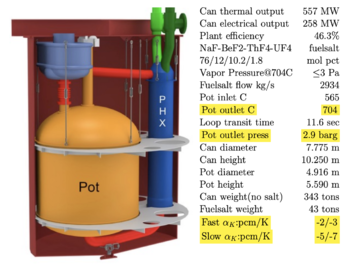

- ↑ Fig.10 from Section 1.2 in ThorConIsle

- ↑ ThorCon Power Conversion.

- ↑ 3.0 3.1 3.2 ThorCon Fuel Cycle

- ↑ ThorCon Isle

- ↑ IAEA Advanced Reactors Information System (ARIS) ThorCon_2020.pdf 2020/06/22.

- ↑ The wall is kept "cold" by water that is replenished from a storage tank above the reactor. Circulation is maintained without pumps, because the hot water (or steam) rises in the space around the cold wall.

- ↑ 7.0 7.1 7.2 7.3 7.4 7.5 ThorCon SpecSheet7

- ↑ See section Release resistance in ThorCon Safety

- ↑ ThorCon Drain tank

- ↑ Section 6.2 in ARIS Status Report

- ↑ ThorCon power plants can store up to 80 years of used fuel onboard, using passive air cooling. ThorCon Fuel

- ↑ ThorCon Economics

- ↑ "ThorCon is Fixable" p.1 in ThorConIsle

- ↑ Hastelloy-N

- ↑ ThorCon graphite specification