User:Milton Beychok/Sandbox

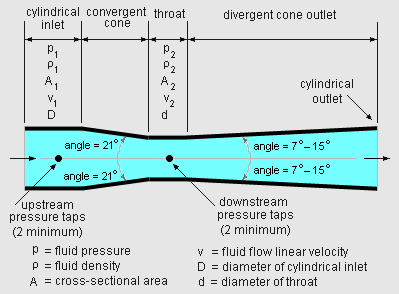

A Venturi tube (or simply a venturi) is a section of piping consisting of an inlet converging conical section leading to a small diameter cylindrical section called the throat, followed by a diverging conical section leading to a cylindrical exit (see the adjacent drawing).

The volumetric flow rate, Q (e.g., m3/s), of a fluid flowing through the venturi at any given point is the product of the cross-sectional area, A (e.g., m2) at that point multiplied by the fluid's linear velocity, v (e.g., m/s), at that point. Since the volumetric flow rate is the same at any point within the venturi, the linear velocity of the fluid traveling through the smaller diameter throat of the venturi must increase which results in a decrease of pressure due to the conservation of energy, one of the conservation laws.

The gain in kinetic energy resulting from the increased linear velocity in the throat is offset (i.e., balanced) by the decrease of pressure in the throat. The reduction in pressure which occurs when the fluid flows through the throat is called the Venturi effect and is named after the Italian physicist Giovanni Battista Venturi (1746 - 1822) who first observed the effect.

Thus, referring to the adjacent drawing, the pressure p2 and the cross-sectional area A2 in the throat are smaller than the pressure p1 and the cross-sectional area A1 in the cylindrical inlet section. The linear velocity v2 in the throat is higher than the linear velocity v1 in the inlet section.

A venturi tube may also consist of non-cylindrical ducting rather than piping.

Measuring fluid flow rate with a venturi

Incompressible fluid

Venturi tubes are used to accurately measure the volumetric flow of an ideal fluid, meaning that the fluid satisfies these conditions:[2][3]

- The fluid is nonviscous: There is no internal friction between layers of the fluid.

- The fluid is incompressible: The density of the fluid is constant (as is the case with liquids)

- The fluid flows without any turbulence: No element of the fluid has any angular velocity about its center, so there are no eddy currents present.

- The fluid flow is steady: The velocity, density and pressure at each point in the fluid does not change with time.

Starting with a common form of the Bernoulli equation for fluid flow:

where ρv2/2 denotes kinetic energy, ρgh denotes gravitational potential energy and:

= the fluid's static pressure = the fluid's density = the fluid's linear velocity = the gravitational acceleration = the height of a given point (in the fluid flow) above any reference plane designated as having zero height

For an incompressible fluid with a constant density and a venturi with a horizontal centerline, the equation simplifies to:

or to:

Since the volumetric flow rate Q is the same at all points in the venturi by the equation of continuity:

then:

which can be re-arranged to:

The actual flow rate through a venturi tube is seldom equal to the theoretical flow rate of an ideal fluid and usually turns out to be less than the theoretical flow rate. In order to account for this difference, a discharge coefficient C is introduced to obtain the final volumetric flow rate equation for an incompressible fluid flowing through a venturi tube with a horizontal centerline:

where:

= the volumetric flow rate of the fluid = the discharge coefficient = (actual flow rate) / (theoretical flow rate = the cross-sectional area of the venturi = the fluid's static pressure = the fluid's density

One method for determining the discharge coefficient is to calibrate the venturi tube on a test stand which is expensive and time consuming. A considerable number of test calibrations have been performed on various venturi tube geometries. As a result, the ASME Standard MFC-3M-1989[1] provides these discharge coefficients for their specified venturi tube geometry (per the diagram at the top of this article) and for three types of fabrication:[4][5]

- For venturi tubes with a welded convergent cone: C = 0.984 (valid for fluid flow Reynolds numbers between 2 × 105 and 6 × 106

- For venturi tubes with an as-cast convergent cone: C = 0.984 (valid for fluid flow Reynolds numbers between 2 × 105 and 6 × 106

- For venturi tubes with a machined convergent cone: C = 0.995 (valid for fluid flow Reynolds numbers between 2 × 105 and 2 × 106

Compressible fluid

For compressible fluids (i.e., a gases), the density is not constant. It will vary from the density (ρ1) at the venturi inlet to the density (ρ2) at the venturi throat. The equation for the mass flow rate of a compressible fluid may be expressed as:[6]

The expansion factor Y allows for the change in gas density as the gas expands adiabatically from the venturi inlet pressure to the reduced pressure at the venturi throat. It may be calculated by using this equation:[6]

Other uses for a venturi

References

- ↑ 1.0 1.1 ASME Standard MFC-3M-1989, Measurement of Fluid Flow in Pipes Using Orifice, Nozzle, and Venturi', American Society of Mechanical Engineers (ASME), New York, 1989.

- ↑ Raymond A. Serway, Chris Vuille and Jerry S. Faughn (2008). College Physics, 8th Edition. Brooks Cole. ISBN 0-495-38693-6.

- ↑ Fluid Flow Parameters

- ↑ ORO-FLOW Users Guide

- ↑ Flowel 3.0 for Windows Flow Element Sizing and Documentation

- ↑ 6.0 6.1 Don W. Green and Robert H. Perry (19845-13). Perry's Chemical Engineers' Handbook, 6th Edition. McGraw-Hill. ISBN 0-07-049479-7. See equations 5-14 and 5-15 on pages 5-12 and 5-13.

![{\displaystyle Q=A_{2}{\sqrt {\frac {2\,(p_{1}-p_{2})}{\rho \left(1-\left[{\frac {A_{2}}{A_{1}}}\right]^{2}\right)}}}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/89934ebcbaa79676066a0cbabe24778cb948e739)

![{\displaystyle Q=CA_{2}{\sqrt {\frac {2\,(p_{1}-p_{2})}{\rho \left(1-\left[{\frac {A_{2}}{A_{1}}}\right]^{2}\right)}}}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/ce3309f1fff02fc9a82bd59f9d8148e0cc95b7be)

![{\displaystyle {\dot {m}}=YCA_{2}\,{\sqrt {\frac {2\,\rho _{1}\,(p_{1}-p_{2})}{1-\beta ^{4}}}}=YCA_{2}\,{\sqrt {\frac {2\,\rho _{1}\,(p_{1}-p_{2})}{\left(1-\left[{\frac {d}{D}}\right]^{4}\right)}}}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/ede373459166d7b6d89c7f0a9caff8d83fab1336)