User:Milton Beychok/Sandbox

A visbreaker is a processing unit in oil refinery whose purpose is to reduce the quantity of residual oil produced in the distillation of crude oil and to increase the yield of more valuable middle distillates (heating oil and diesel) by the refinery. A visbreaker thermally cracks large hydrocarbon molecules in the oil by heating in a furnace to reduce its viscosity and to produce small quantities of light hydrocarbons (LPG and gasoline).[1][2][3] The process name of "visbreaker" refers to the fact that the process reduces (i.e., breaks) the viscosity of the residual oil. The process is non-catalytic.

Process objectives

The objectives of visbreaking are:

- Reduce the viscosity of the feed stream: Typically this is the residue from vacuum distillation of crude oil but can also be the residue from hydroskimming operations, natural bitumen from seeps in the ground or tar sands, and even certain high viscosity crude oils.

- Reduce the amount of residual fuel oil produced by a refinery: Residual fuel oil is generally regarded as a low value product. Demand for residual fuel continues to decrease as it is replaced in its traditional markets, such as fuel needed to generate steam in power stations, by cleaner burning alternative fuels such as natural gas.

- Increase the proportion of middle distillates in the refinery output: Middle distillate is used as a diluent with residual oils to bring their viscosity down to a marketable level. By reducing the viscosity of the residual stream in a visbreaker, a fuel oil can be made using less diluent and the middle distillate saved can be diverted to higher value diesel or heating oil manufacture.

Technology

Coil visbreaking

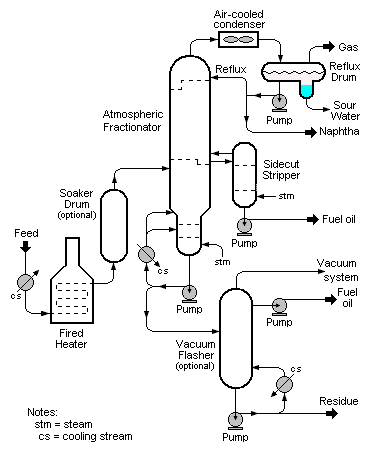

The term coil (or furnace) visbreaking is applied to units where the cracking process occurs in the furnace tubes (or "coils"). Material exiting the furnace is quenched to halt the cracking reactions: frequently this is achieved by heat exchange with the virgin material being fed to the furnace, which in turn is a good energy efficiency step, but sometimes a stream of cold oil (usually gas oil) is used to the same effect. The gas oil is recovered and re-used. Providers of coil visbreaking technology include the Foster Wheeler corporation. The extent of the cracking reaction is controlled by regulation of the speed of flow of the oil through the furnace tubes. The quenched oil then passes to a fractionator where the products of the cracking (gas, LPG, gasoline, gas oil and tar) are separated and recovered.

Soaker visbreaking

In soaker visbreaking, the bulk of the cracking reaction occurs not in the furnace but in a drum located after the furnace called the soaker. Here the oil is held at an elevated temperature for a pre-determined period of time to allow cracking to occur before being quenched. The oil then passes to a fractionator. In soaker visbreaking, lower temperatures are used than in coil visbreaking. The comparatively long duration of the cracking reaction is used instead.

Visbreaker tar can be further refined by feeding it to a vacuum fractionator. Here additional heavy gas oil may be recovered and routed either to catalytic cracking, hydrocracking or thermal cracking units on the refinery. The vacuum-flashed tar (sometimes referred to as pitch) is then routed to fuel oil blending. In a few refinery locations, visbreaker tar is routed to a delayed coker for the production of certain specialist cokes such as anode coke or needle coke.

Soaker visbreaking versus coil visbreaking

From the standpoint of yield, there is little or nothing to choose between the two approaches. However, each offers significant advantages in particular situations:

- De-coking: The cracking reaction forms petroleum coke as a byproduct. In coil visbreaking, this lays down in the tubes of the furnace and will eventually lead to fouling or blocking of the tubes. The same will occur in the drum of a soaker visbreaker, though the lower temperatures used in the soaker drum lead to fouling at a much slower rate. Coil visbreakers therefore require frequent de-coking. This is quite labour intensive, but can be developed into a routine where tubes are de-coked sequentially without the need to shutdown the visbreaking operation. Soaker drums require far less frequent attention but their being taken out of service normally requires a complete halt to the operation. Which is the more disruptive activity will vary from refinery to refinery.

- Fuel Economy: The lower temperatures used in the soaker approach mean that these units use less fuel. In cases where a refinery buys fuel to support process operations, any savings in fuel consumption could be extremely valuable. In such cases, soaker visbreaking may be advantageous.

Quality and yields

Feed quality and product quality

The quality of the feed going into a visbreaker will vary considerably with the type of crude oil that the refinery is processing. The following is a typical quality for the vacuum distillation residue of Arabian light (a crude oil from Saudi Arabia and widely refined around the world):

| Density (kg/l) |

Viscosity at 100 °C (centistokes) |

Sulphur Content (wt%) |

|---|---|---|

| 1.020 | 930 | 4.0 |

Once this material has been run through a visbreaker (and, again, there will be considerable variation from visbreaker to visbreaker as no two will operate under exactly the same conditions) the reduction in viscosity is dramatic:

| Density (kg/l) |

Viscosity at 100 °C (centistokes) |

Sulphur Content (wt%) |

|---|---|---|

| 1.048 | 115 | 4.7 |

Yields

The yields of the various hydrocarbon products will depend on the "severity" of the cracking operation as determined by the temperature the oil is heated to in the visbreaker furnace. At the low end of the scale, a furnace heating to 425 °C would crack only mildly, while operations at 500 °C would be considered as very severe. Arabian light crude residue when visbroken at 450 °C would yield around 76% (by weight) of tar, 15% middle distillates, 6% gasolines and 3% gas and LPG.

- ↑ James H. Gary and Glenn E. Handwerk (1984). Petroleum Refining Technology and Economics, 2nd Edition. Marcel Dekker, Inc. ISBN 0-8247-7150-8.

- ↑ Robert E. Maples (2000). Petroleum Refinery Process Economics, 2nd Edition. Pennwell Books. ISBN 0-87814-779-9.

- ↑ James G. Speight (2006). The Chemistry and Technology of Petroleum. CRC Press. ISBN 0-8493-9067-2.