User:Milton Beychok/Sandbox

This need a lot of work-over yet before it is a CZ article

Asphalt is a sticky, black and highly viscous liquid or semi-solid that is present in most petroleum crude oils and in some natural deposits. The asphalt molecules are called asphaltenes and they are defined as the fraction of petroleum crude oil that is separated from the crude oil by precipitation upon the addition of hydrocarbon solvents such as propane, pentane, hexane or heptane. They are high molecular weight (800 - 2500 g/mole) compounds existing in the form of flat sheets consisting of polyaromatic condensed rings with short aliphatic chains

Petroleum asphalt is sometimes referred to as bitumen, asphaltum or pitch. The terminology varies from country to country and from individual to individual. Asphalt is often confused with coal tar (or coal pitch) derived from the pyrolosis of coal and which has a different chemical structure than asphalt.

When petroleum asphalt is combined with construction aggregate (sand, gravel, crushed stone, etc.) for use in road construction, it is often referred to as asphaltic concrete or asphaltic cement (see Asphalt (paving).

The natural deposits of asphalt (often referred to as tar) include asphaltic lakes such as Bermudez Lake in Venezuela, and Pitch Lake in [[Trinidad. Other natural deposits include tar sands (sometimes called oil sands) and the two largest deposits of tar sans are such as in Alberta, Canada and the Orinoco Oil Belt area of Venezuela.

Background

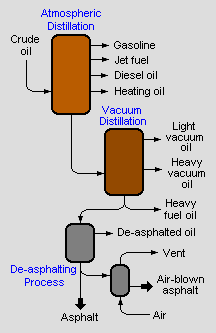

Asphalt can be separated from the other components in crude oil (such as naphtha, gasoline and diesel) by the process of fractional distillation, usually under vacuum conditions. A better separation can be achieved by further processing of the heavier fractions of the crude oil in a de-asphalting unit, which uses either propane or butane in a supercritical phase to dissolve the lighter molecules which are then separated. Further processing is possible by "blowing" the product: namely reacting it with oxygen. This makes the product harder and more viscous.

.

Asphalt is typically stored and transported at temperatures around 300 degrees Fahrenheit (150° C). Sometimes diesel oil or kerosene are mixed in before shipping to retain liquidity; upon delivery, these lighter materials are separated out of the mixture. This mixture is often called bitumen feedstock, or BFS. Some dump trucks route the hot engine exhaust through pipes in the dump body to keep the material warm. The backs of tippers carrying asphalt, as well as some handling equipment, are also commonly sprayed with a releasing agent before filling to aid release. Diesel oil is sometimes used as a release agent, although it can mix with and thereby reduce the quality of the asphalt.

Uses

Historical uses

In the ancient Middle East, natural asphalt deposits were used for mortar between bricks and stones, ship caulking, and waterproofing. The Persian word for asphalt is mumiya, which may be related to the English word mummy. Asphalt was also used by ancient Egyptians to embalm mummies.

In the ancient Far East, natural asphalt was slowly boiled to get rid of the higher fractions, leaving a material of higher molecular weight which is thermoplastic and when layered on objects, became quite hard upon cooling. This was used to cover scabbards and other objects that needed water-proofing. Statuettes of household deities were also cast with this type of material in Japan, and probably also in China.Template:Facts

In North America archaeological recovery has indicated that asphaltum was sometimes used to apply stone projectile points to a wooden haft.[1]

Poured bitumen has also been used as a damp-proof course in building.

Road construction

Rolled asphalt concrete

The largest use of asphalt is for making asphalt concrete for road surfaces and accounts for approximately 80% of the asphalt consumed in the United States. Due to its highly viscous nature, asphalt is commonly heated for road construction to make it soft and easy to work. Special heated tanker trucks are employed in road building to apply hot asphalt to the road bed.[2]

Asphalt road surface is the most widely recycled material in the US, both by gross tonnage and by percentage. According to a report issued by the Federal Highway Administration and the United States Environmental Protection Agency, 80% of the asphalt from road surfaces' that is removed each year during widening and resurfacing projects is reused as part of new roads, roadbeds, shoulders and embankments.

Roofing shingles account for most of the remaining asphalt consumption. Other uses include cattle sprays, fence post treatments, and waterproofing for fabrics.

Mastic asphalt

Mastic asphalt is a type of asphalt which differs from dense graded asphalt (asphalt concrete) in that it has a higher bitumen (binder) content, usually around 7-10% of the whole aggregate mix, as opposed to roller asphalt, which has only around 5% added bitumen. Another asphalt which is fast gaining global popularity is stone mastic asphalt (SMA). SMA's advantages over rolled asphalt is its high anti skid qualities due to its high aggregate density and the lack of void content (air pockets). Another advantage of SMA is its longer durability over alternative road asphalt surfaces, but its manufacture and application, if not controlled closely, can result in slippery road surfaces due to excess bitumen pooling (bleeding) onto the surface.

Ashphalt is widely used in airports around the world. Due to the sturdiness, it is widely used for runways dedicated to aircraft landing and taking off.

Asphalt emulsion

A number of technologies allow asphalt to be mixed at much lower temperatures. These involve mixing the asphalt with petroleum solvents to form "cutbacks" with reduced melting point or mixtures with water to turn the asphalt into an emulsion. Asphalt emulsions contain up to 70% asphalt and typically less than 1.5% chemical additives. There are two main types of emulsions with different affinity for aggregates, cationic and anionic. Asphalt emulsions are used in a wide variety of applications. Chipseal involves spraying the road surface with asphalt emulsion followed by a layer of crushed rock or gravel. Slurry Seal involves the creation of a mixture of asphalt emulsion and fine crushed aggregate that is spread on the surface of a road. Cold mixed asphalt can also be made from asphalt emulsion to create pavements similar to hot-mixed asphalt, several inches in depth and asphalt emulsions are also blended into recycled hot-mix asphalt to create low cost pavements.

References

- ↑ C.Michael Hogan (2008) Morro Creek, ed. by A. Burnham [1]

- ↑ An early 1919 hot asphalt tanker truck used for road repair in France after World War 1 -- How Yankee Ingenuity Built Roads in Devasted France, Popular Science monthly, January 1919, page 58, Scanned by Google Books: http://books.google.com/books?id=HykDAAAAMBAJ&pg=PA58

- Barth, Edwin J., Asphalt: Science and Technology Gordon and Breach (1962). ISBN 0-677-00040-5.