User:Milton Beychok/Sandbox: Difference between revisions

imported>Milton Beychok No edit summary |

imported>Milton Beychok |

||

| Line 13: | Line 13: | ||

A de Laval nozzle was used in the first liquid fuel rocket engine designed and launched in 1926 by [[Robert Goddard (scientist)|Robert Goddard]], an [[American]] physicist and rocket pioneer.<ref>{{citation||title=The First Liquid Fuel Rocket|publisher=[[Goddard Space Flight Center]], [[National Aeronautics and Space Administration]]| url=http://www.gsfc.nasa.gov/gsfc/service/gallery/fact_sheets/general/frocket/frocket.htm}}</ref> It is now used in nearly all modern rocket engines propelled by the hot gases produced by [[combustion]] of a fuel. | A de Laval nozzle was used in the first liquid fuel rocket engine designed and launched in 1926 by [[Robert Goddard (scientist)|Robert Goddard]], an [[American]] physicist and rocket pioneer.<ref>{{citation||title=The First Liquid Fuel Rocket|publisher=[[Goddard Space Flight Center]], [[National Aeronautics and Space Administration]]| url=http://www.gsfc.nasa.gov/gsfc/service/gallery/fact_sheets/general/frocket/frocket.htm}}</ref> It is now used in nearly all modern rocket engines propelled by the hot gases produced by [[combustion]] of a fuel. | ||

== | ==Conceptual mechanism and assumptions== | ||

The conceptual analysis of gas flow through a de Laval nozzle involves a number of assumptions: | |||

* For simplicity, the gas is assumed to be an [[ideal gas]]. | |||

* The gas flow is [[Isentropic process|isentropic]] (i.e., at constant [[entropy]]), [[Sliding friction|frictionless]], and [[adiabatic]] (i.e., there is little or no [[heat]] gained or lost). | |||

* The gas flow is constant (i.e., steady) during the period of the [[propellant]] burn. | |||

* The gas flow is along a straight line from gas inlet to exhaust gas exit (i.e., along the nozzle's axis of symmetry) | |||

* The gas flow behavior is that of a compressible fluid (as distinguished from liquids which are incompressible fluids). | |||

The linear [[velocity]] of a ''[[subsonic]]'' <ref name=sonic>If a gas flow linear velocity is lower than the [[speed of sound]] in that gas, it is referred to as ''subsonic'' flow. If the linear velocity is equal to the speed of sound, it is referred to as ''sonic''. If the linear velocity is higher than the speed of sound, it is referred to as ''supersonic''.</ref> gas will increase if the pipe or other conduit carrying it narrows because the mass flow rate is constant. At subsonic linear velocities, the gas is compressible and [[sound]] (which is a longitudinal [[pressure wave]]) will propagate through it. Under certain conditions, the gas velocity at the "throat" of a de Laval nozzle, where the cross-sectional area is at a minimum, becomes ''[[sonic]]'' <ref name=sonic/> (denoted as having a [[Mach number]] = 1.0) under certain conditions<ref>Choked flow usually occurs when the absolute pressure of the gas upstream of the nozzle throat is at least 1.7 to 1.9 times as high as the absolute pressure of the gas downstream of the throat.</ref> and is commonly referred to as [[choked flow]]. As the nozzle's cross-sectional area increases in the divergent section, the gas expands and the linear velocity of the gas flow becomes [[supersonic]] <ref name=sonic/> and sound waves can no longer propagate backwards through the gas. | |||

If the gas flow through a de Laval nozzle is not at choked flow conditions, supersonic flow flow will not occur in the gas expansion section downstream of the nozzle throat and the de Laval nozzle will essentially act as a [[Venturi tube]]. | |||

Even when the gas flow through the throat of the de Laval nozzle is choked, the exhaust gas pressure at the exit of the expansion (diverging) part of the nozzle must not be too low. Since the external ambient pressure cannot travel upstream against the supersonic exhaust flow, the exit pressure can be significantly below the external ambient pressure into which the gas exhausts. However, if the exit pressure is too far below the ambient pressure, then the exhaust gas flow will cease to be supersonic, or the flow will separate within the expansion portion of the nozzle, forming an unstable jet that may "flop" around within the nozzle, possibly damaging it. | |||

In practice, the external ambient pressure must be no higher than approximately 2-3 times the pressure of the | |||

supersonic exhaust gas at the nozzle exit. | |||

==Exhaust gas velocity== | ==Exhaust gas velocity== | ||

Revision as of 18:44, 2 April 2010

A de Laval nozzle (also convergent-divergent nozzle) is a tube that is pinched in the middle, making a carefully balanced, asymmetric hourglass-shape. It is used to accelerate a hot, pressurized gas passing through it to a supersonic speed, and upon expansion, to shape the exhaust flow so that the heat energy propelling the flow is maximally converted into directed kinetic energy.

The de Lava nozzle is widely used in some types of steam turbine and it is an essential part of modern rocket engines as well as being used in supersonic jet engines.

Similar flow properties have been ascribed to jet streams within astrophysics.[1]

History

The nozzle was developed by Swedish inventor Gustaf de Laval in 1888 for use on an impulse steam turbine.[2][3][4]

A de Laval nozzle was used in the first liquid fuel rocket engine designed and launched in 1926 by Robert Goddard, an American physicist and rocket pioneer.[5] It is now used in nearly all modern rocket engines propelled by the hot gases produced by combustion of a fuel.

Conceptual mechanism and assumptions

The conceptual analysis of gas flow through a de Laval nozzle involves a number of assumptions:

- For simplicity, the gas is assumed to be an ideal gas.

- The gas flow is isentropic (i.e., at constant entropy), frictionless, and adiabatic (i.e., there is little or no heat gained or lost).

- The gas flow is constant (i.e., steady) during the period of the propellant burn.

- The gas flow is along a straight line from gas inlet to exhaust gas exit (i.e., along the nozzle's axis of symmetry)

- The gas flow behavior is that of a compressible fluid (as distinguished from liquids which are incompressible fluids).

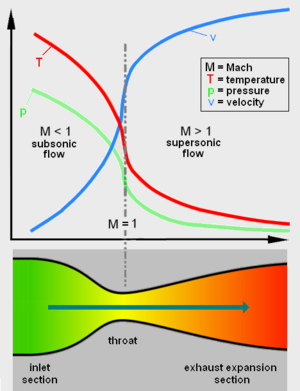

The linear velocity of a subsonic [6] gas will increase if the pipe or other conduit carrying it narrows because the mass flow rate is constant. At subsonic linear velocities, the gas is compressible and sound (which is a longitudinal pressure wave) will propagate through it. Under certain conditions, the gas velocity at the "throat" of a de Laval nozzle, where the cross-sectional area is at a minimum, becomes sonic [6] (denoted as having a Mach number = 1.0) under certain conditions[7] and is commonly referred to as choked flow. As the nozzle's cross-sectional area increases in the divergent section, the gas expands and the linear velocity of the gas flow becomes supersonic [6] and sound waves can no longer propagate backwards through the gas.

If the gas flow through a de Laval nozzle is not at choked flow conditions, supersonic flow flow will not occur in the gas expansion section downstream of the nozzle throat and the de Laval nozzle will essentially act as a Venturi tube.

Even when the gas flow through the throat of the de Laval nozzle is choked, the exhaust gas pressure at the exit of the expansion (diverging) part of the nozzle must not be too low. Since the external ambient pressure cannot travel upstream against the supersonic exhaust flow, the exit pressure can be significantly below the external ambient pressure into which the gas exhausts. However, if the exit pressure is too far below the ambient pressure, then the exhaust gas flow will cease to be supersonic, or the flow will separate within the expansion portion of the nozzle, forming an unstable jet that may "flop" around within the nozzle, possibly damaging it.

In practice, the external ambient pressure must be no higher than approximately 2-3 times the pressure of the supersonic exhaust gas at the nozzle exit.

Exhaust gas velocity

As the gas enters a nozzle, it is traveling at subsonic velocities. As the throat contracts down the gas is forced to accelerate until at the nozzle throat, where the cross-sectional area is the smallest, the linear velocity becomes sonic. From the throat the cross-sectional area then increases, the gas expands and the linear velocity becomes progressively more supersonic.

The linear velocity of the exiting exhaust gases can be calculated using the following equation:[8][9][10]

| where: | |

| Ve | = Exhaust velocity at nozzle exit, m/s |

| T | = absolute temperature of inlet gas, K |

| R | = Universal gas law constant = 8314.5 J/(kmol·K) |

| M | = the gas molecular mass, kg/kmol (also known as the molecular weight) |

| k | = cp/cv = isentropic expansion factor |

| cp | = specific heat of the gas at constant pressure |

| cv | = specific heat of the gas at constant volume |

| Pe | = absolute pressure of exhaust gas at nozzle exit, Pa |

| P | = absolute pressure of inlet gas, Pa |

Some typical values of the exhaust gas velocity Ve for rocket engines burning various propellants are:

- 1700 to 2900 m/s (3,800 to 6,500 mph) for liquid monopropellants

- 2900 to 4500 m/s (6,500 to 10,100 mph) for liquid bipropellants

- 2100 to 3200 m/s (4,700 to 7,200 mph) for solid propellants

As a note of interest, Ve is sometimes referred to as the ideal exhaust gas velocity because it based on the assumption that the exhaust gas behaves as an ideal gas.

As an example calculation using the above equation, assume that the propellant combustion gases are: at an absolute pressure entering the nozzle of P = 7.0 MPa and exit the rocket exhaust at an absolute pressure of Pe = 0.1 MPa; at an absolute temperature of T = 3500 K; with an isentropic expansion factor of k = 1.22 and a molar mass of M = 22 kg/kmol. Using those values in the above equation yields an exhaust velocity Ve = 2802 m/s or 2.80 km/s which is consistent with above typical values.

The technical literature can be very confusing because many authors fail to explain whether they are using the universal gas law constant R which applies to any ideal gas or whether they are using the gas law constant Rs which only applies to a specific individual gas. The relationship between the two constants is Rs = R/M.

Application to astrophysics

Theoretical astrophysicists have found that pipes with the flow pattern of a De Laval nozzle have analogous phenomena in the interstellar medium. The interior of an accretion disk has a similar function as the pipe, save it is not a solid wall, but itself a fluid that can contain a relativistic jet by a pressure balanced boundary.

References

- ↑ Catherine J. Clarke and Bob Carswell (2007). Principles of Astrophysical Fluid Dynamics, 1st Edition. Cambridge University Press, page 226. ISBN 0-521-85331-1. See Chapter 9, section 9.2

- ↑ British patent 7143 of 1889.

- ↑ Theodore Stevens and Henry Metcalfe Hobart (1906). Steam Turbine Engineering. The MacMillan Co., pp. 24-27. PDF download available on-line at Google books

- ↑ Robert M. Neilson (1903). The Steam Turbine, 3rd Edition. Longmans, Green, and Co., pp. 102-103. PDF download available on-line at Google books

- ↑ The First Liquid Fuel Rocket, Goddard Space Flight Center, National Aeronautics and Space Administration

- ↑ 6.0 6.1 6.2 If a gas flow linear velocity is lower than the speed of sound in that gas, it is referred to as subsonic flow. If the linear velocity is equal to the speed of sound, it is referred to as sonic. If the linear velocity is higher than the speed of sound, it is referred to as supersonic.

- ↑ Choked flow usually occurs when the absolute pressure of the gas upstream of the nozzle throat is at least 1.7 to 1.9 times as high as the absolute pressure of the gas downstream of the throat.

- ↑ Richard Nakka's Equation 12

- ↑ Robert Braeuning's Equation 1.22

- ↑ George P. Sutton (1992). Rocket Propulsion Elements: An Introduction to the Engineering of Rockets, 6th Edition. Wiley-Interscience, page 636. ISBN 0-471-52938-9.

Bibliography:

- Garrett Scaife (2000). From Galaxies to Turbines: Science, Technology, and the Parsons Family. Taylor & Francis Group, page 197. ISBN 0-7503-0582-7. Available on-line at Google books

- John David Anderson (2003). Modern Compressible Flow: With Historical Perspective, 3rd Edition. McGraw-Hill, page 229. ISBN 0-07-242443-5. Available on-line at Google books

![{\displaystyle V_{e}={\sqrt {\;{\frac {T\;R}{M}}\cdot {\frac {2\;k}{k-1}}\cdot {\bigg [}1-(P_{e}/P)^{(k-1)/k}{\bigg ]}}}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/77732f6d675523fe2d722db752ab4f6cb6d0acc3)