User:Milton Beychok/Sandbox: Difference between revisions

imported>Milton Beychok mNo edit summary |

imported>Milton Beychok |

||

| Line 3: | Line 3: | ||

Removal of the salts, water and sediment is necessary to avoid excessive | Removal of the salts, water and sediment is necessary to avoid excessive | ||

==The salt, water and sediment in crude oil received by refineries== | ==The salt, water and sediment in crude oil as received by refineries== | ||

The amount of water, salts and sediment in the crude oil as received at petroleum refineries varies widely with the source of the crude oil, the prior processing of the crude oil at the source sites and with the mode of transporting the crude oil from its source to the refineries. | The amount of water, salts and sediment in the crude oil as received at petroleum refineries varies widely with the source of the crude oil, the prior processing of the crude oil at the source sites and with the mode of transporting the crude oil from its source to the refineries. | ||

| Line 16: | Line 16: | ||

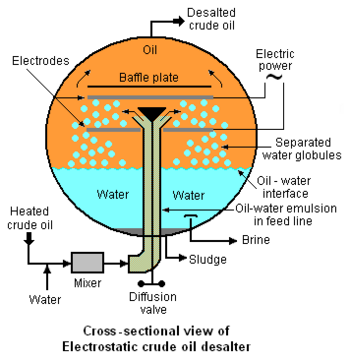

|{{Image|Desalter Diagram.png|right|350px|Figure 2: Cross-sectional diagram of a crude oil desalter}} | |{{Image|Desalter Diagram.png|right|350px|Figure 2: Cross-sectional diagram of a crude oil desalter}} | ||

|} | |} | ||

==References== | ==References== | ||

{{reflist}} | {{reflist}} | ||

Revision as of 19:57, 26 January 2010

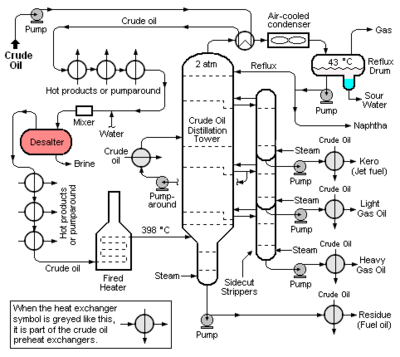

A crude oil desalter is a device used in petroleum refineries to remove inorganic salts, water and sediment from the incoming petroleum crude oil feedstock before it is refined. This article focuses on the use of electrostatic desalters to separarate dehydrated, desalted crude oil from the water, salts and sediment.[1][2][3][4] Almost all refineries now use electrostatic desalters. However, there may still be a few refineries employing the older, less efficient method that utilized chemicals and settling tanks.

Removal of the salts, water and sediment is necessary to avoid excessive

The salt, water and sediment in crude oil as received by refineries

The amount of water, salts and sediment in the crude oil as received at petroleum refineries varies widely with the source of the crude oil, the prior processing of the crude oil at the source sites and with the mode of transporting the crude oil from its source to the refineries.

References

- ↑ Jean-Pierre Wauquier (Editor) (2000). Petroleum Refining, Volume 2, Separation Processes. Editions Technip. ISBN 2-7108-0761-0. Limited preview in Google Books

- ↑ Francis S. Manning and Richard E. Thompson (1995). Oilfield Processing, Volume 2: Crude oil. Pennwell Books. ISBN 0-87814-354-8. Limited preview in Google Books

- ↑ Beychok, Milton R. (1967). Aqueous Wastes from Petroleum and Petrochemical Plants. John Wiley & Sons. Library of Congress Control Number 67019834.

- ↑ Petroleum Wastewater – A Case Study Greg Johnson (from Water and Wastewater.com)