User:Milton Beychok/Sandbox: Difference between revisions

imported>Milton Beychok No edit summary |

imported>Milton Beychok No edit summary |

||

| Line 1: | Line 1: | ||

A '''process flow diagram''' (PFD) is a diagram commonly used in [[chemical engineering|chemical]] and [[process engineering]] to indicate the general flow of plant processes and equipment. The PFD displays the relationship between ''major'' equipment of a plant facility and does not show minor details such as piping details and designations. Another commonly-used term for a PFD is a ''flowsheet''. | |||

==Typical content of a process flow diagram== | |||

[[Image:pfd-symbols.png|thumb|right|350px|Some typical elements from process flow diagrams, as provided by the [[open source]] program, [[Dia (software)|Dia]].]] | |||

Typically, process flow diagrams of a single [[unit process]] will include the following: | |||

* Process piping | |||

* Major bypass and recirculation lines | |||

* Major equipment symbols, names and identification numbers | |||

* Flow directions | |||

* Control loops that affect operation of the system | |||

* Interconnection with other systems | |||

* System ratings and operational values as minimum, normal and maximum flow, temperature and pressure | |||

* Composition of fluids | |||

Process flow diagrams generally do not include: | |||

* Pipe classes or piping line numbers | |||

* Process control instrumentation (sensors and final elements) | |||

* Minor bypass lines | |||

* Isolation and shutoff valves | |||

* Maintenance vents and drains | |||

* [[Relief valve|Relief]] and [[safety valve]]s | |||

* Flanges | |||

Process flow diagrams of multiple process units within a large industrial plant will usually contain less detail and may be called ''block flow diagrams'' or ''schematic flow diagrams''. | |||

==Process flow diagram examples== | |||

=== Single process unit=== | |||

The process flow diagram below depicts a single chemical engineering unit process known as an [[Amine treating|amine treating plant]]: | |||

[[Image:AmineTreating.png|frame|center|Flow diagram of a typical amine treating process used in industrial plants]] | |||

=== Multiple process units within an industrial plant=== | |||

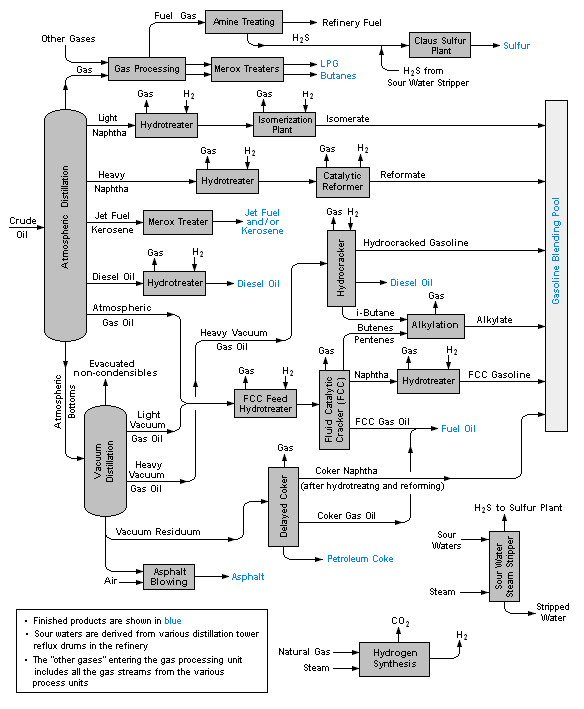

The process flow diagram below is an example of a schematic or block flow diagram and depicts the various unit processes within a typical [[oil refinery]]: | |||

[[Image:RefineryFlow.png|center|frame|A typical oil refinery]] | |||

==Other items of interest== | |||

A PFD can be computer generated from process simulators (see [[List of Chemical Process Simulators]]), CAD packages, or flow chart software using a library of chemical engineering symbols. Rules and symbols are available from standardization organizations such as [[DIN]], [[ISO]] or [[ANSI]]. Often PFDs are produced on large sheets of paper. | |||

PFDs of many commercial processes can be found in the literature, specifically in encyclopedias of chemical technology, although some might be outdated. To find recent ones, patent databases such as those available from the [[United States Patent and Trademark Office]] can be useful. | |||

==Standards== | |||

* ISO 10628: Flow Diagrams For Process Plants - General Rules | |||

* ANSI Y32.11: Graphical Symbols For Process Flow Diagrams (withdrawn 2003) | |||

* SAA AS 1109: Graphical Symbols For Process Flow Diagrams For The Food Industry | |||

== References == | |||

== Further reading == | |||

* {{cite book|author=Raymond E. Kirk and Donald F. Othmer|title=Kirk-Othmer Encyclopedia of Chemical Technology|edition=4th|publisher=Wiley-Interscience|year=2001|isbn=0471419613}} | |||

*{{cite book|author=M.S. Ray and M.G. Sneesby|title=Chemical Engineering Design Project: A Case Study Approach|edition=2nd|publisher=Gordan and Breach Science Publishers|year=1998|isbn=9056991361}} | |||

*{{cite book|author=R. Turton, R.C. Bailie, W.B. Whiting and J.S. Shaeiwitz|title=Analysis, Synthesis, and Design of Chemical Processes|edition=2nd|publisher=Prentice Hall|year=2002|isbn=0-13-064792-6}} | |||

* {{cite book|author=Fritz Ullmann|title=Ullman’s Encyclopedia of Industrial Chemistry|edition=6th|publisher=Wiley-VCH|year=2002|isbn=3-527-30385-5}} | |||

Revision as of 16:47, 6 June 2009

A process flow diagram (PFD) is a diagram commonly used in chemical and process engineering to indicate the general flow of plant processes and equipment. The PFD displays the relationship between major equipment of a plant facility and does not show minor details such as piping details and designations. Another commonly-used term for a PFD is a flowsheet.

Typical content of a process flow diagram

Typically, process flow diagrams of a single unit process will include the following:

- Process piping

- Major bypass and recirculation lines

- Major equipment symbols, names and identification numbers

- Flow directions

- Control loops that affect operation of the system

- Interconnection with other systems

- System ratings and operational values as minimum, normal and maximum flow, temperature and pressure

- Composition of fluids

Process flow diagrams generally do not include:

- Pipe classes or piping line numbers

- Process control instrumentation (sensors and final elements)

- Minor bypass lines

- Isolation and shutoff valves

- Maintenance vents and drains

- Relief and safety valves

- Flanges

Process flow diagrams of multiple process units within a large industrial plant will usually contain less detail and may be called block flow diagrams or schematic flow diagrams.

Process flow diagram examples

Single process unit

The process flow diagram below depicts a single chemical engineering unit process known as an amine treating plant:

Multiple process units within an industrial plant

The process flow diagram below is an example of a schematic or block flow diagram and depicts the various unit processes within a typical oil refinery:

Other items of interest

A PFD can be computer generated from process simulators (see List of Chemical Process Simulators), CAD packages, or flow chart software using a library of chemical engineering symbols. Rules and symbols are available from standardization organizations such as DIN, ISO or ANSI. Often PFDs are produced on large sheets of paper.

PFDs of many commercial processes can be found in the literature, specifically in encyclopedias of chemical technology, although some might be outdated. To find recent ones, patent databases such as those available from the United States Patent and Trademark Office can be useful.

Standards

- ISO 10628: Flow Diagrams For Process Plants - General Rules

- ANSI Y32.11: Graphical Symbols For Process Flow Diagrams (withdrawn 2003)

- SAA AS 1109: Graphical Symbols For Process Flow Diagrams For The Food Industry

References

Further reading

- Raymond E. Kirk and Donald F. Othmer (2001). Kirk-Othmer Encyclopedia of Chemical Technology, 4th. Wiley-Interscience. ISBN 0471419613.

- M.S. Ray and M.G. Sneesby (1998). Chemical Engineering Design Project: A Case Study Approach, 2nd. Gordan and Breach Science Publishers. ISBN 9056991361.

- R. Turton, R.C. Bailie, W.B. Whiting and J.S. Shaeiwitz (2002). Analysis, Synthesis, and Design of Chemical Processes, 2nd. Prentice Hall. ISBN 0-13-064792-6.

- Fritz Ullmann (2002). Ullman’s Encyclopedia of Industrial Chemistry, 6th. Wiley-VCH. ISBN 3-527-30385-5.