User:Milton Beychok/Sandbox: Difference between revisions

imported>Milton Beychok |

imported>Milton Beychok |

||

| Line 32: | Line 32: | ||

[[Image:Fluid catalytic cracker power recovery.png|right|thumb|350px|{{#ifexist:Template:Fluid catalytic cracker power recovery.png/credit|{{Fluid catalytic cracker power recovery.png/credit}}<br/>|}}Fig. 3: A schematic diagram of the power recovery system in a fluid catalytic cracking unit.]] | [[Image:Fluid catalytic cracker power recovery.png|right|thumb|350px|{{#ifexist:Template:Fluid catalytic cracker power recovery.png/credit|{{Fluid catalytic cracker power recovery.png/credit}}<br/>|}}Fig. 3: A schematic diagram of the power recovery system in a fluid catalytic cracking unit.]] | ||

The combustion flue gas from the catalyst regenerator of a [[fluid catalytic cracker]] is at a temperature of about 715 °C and at a pressure of 2.4 [[bar (unit)#Absolute pressure and gauge pressure|barg]]. | The [[combustion]] [[flue gas]] from the catalyst regenerator of a [[fluid catalytic cracker]] is at a temperature of about 715 °C and at a pressure of about 2.4 [[bar (unit)#Absolute pressure and gauge pressure|barg]]. Its gaseous components are mostly [[carbon monoxide]] (CO), [[carbon dioxide]] (CO<sub>2</sub>) and [[nitrogen]] (N<sub>2</sub>). Although the flue gas has been through two stages of [[Cyclone sparator|cyclones]] (located within the regenerator) to remove entrained catalyst fines, it still contains some residual catalyst fines. | ||

Figure 3 depicts how power is recovered and utilized by routing the regenerator flue gas through an expansion turbine. After the flue gas exits the regenerator, it is routed through a secondary catalyst separator containing ''[[swirl tubes]]'' designed to remove 70 to 90 percent of the residual catalyst fines.<ref>{{cite book|author=Alex C. Hoffnab and Lewis E. Stein|title=Gas Cyclones and Swirl Tubes:Principles , Design and Operation|edition=1st Edition|publisher=Springer|year=2002|id=ISBN 3-540-43326-0}}</ref> This is required to prevent erosion damage to the expansion turbine. | |||

As shown in Figure 3, expansion of the flue gas through an expansion turbine provides sufficient power to drive the regenerator's combustion air [[compressor]]. The electrical [[motor-generator]] in the power recovery system can consume or produce electrical power. If the expansion of the flue gas does not provide enough power to drive the air compressor, the electric motor-generator provides the needed additional power. If the flue gas expansion provides more power than needed to drive the air compressor, than the electric motor-generator converts the excess power into electric power and exports it to the refinery's electrical system.<ref name=Reza/> The [[steam turbine]] shown in Figure 3 is used to drive the regenerator's combustion air compressor during start-ups of the fluid catalytic cracker until there is sufficient combustion flue gas to take over that task. | |||

The expanded flue gas is then routed through a steam-generating [[boiler]] (referred to as a ''CO boiler'') where the carbon monoxide in the flue gas is burned as fuel to provide steam for use in the refinery.<ref name=Reza/> | |||

The expanded flue gas is then routed through a steam-generating [[boiler]] (referred to as a ''CO boiler'') where the carbon monoxide in the flue gas is burned as fuel to provide steam for use in the refinery | |||

The flue gas from the CO boiler is processed through an [[electrostatic precipitator]] (ESP) to remove residual [[particulate matter]]. The ESP removes particulates in the size range of 2 to 20 [[micron (unit)|microns]] from the flue gas.<ref name=Reza/> | |||

[[Image:Expansion turbine+compressor refrigeration system.png|right|thumb|350px|{{#ifexist:Template:Expansion turbine+compressor refrigeration system.png/credit|{{Expansion turbine+compressor refrigeration system.png/credit}}<br/>|}}Fig. 4: Schematic diagram of a refrigeration system using an expansion turbine and a compressor.]] | [[Image:Expansion turbine+compressor refrigeration system.png|right|thumb|350px|{{#ifexist:Template:Expansion turbine+compressor refrigeration system.png/credit|{{Expansion turbine+compressor refrigeration system.png/credit}}<br/>|}}Fig. 4: Schematic diagram of a refrigeration system using an expansion turbine and a compressor.]] | ||

Revision as of 15:01, 11 July 2008

An expansion turbine, also referred to as a turboexpander or turbo-expander, is a centrifugal or axial flow turbine through which a high pressure gas is expanded to produce work that is often used to drive a gas compressor.

Because work is extracted from the expanding high pressure gas, the expansion is an isentropic process (i.e., a constant entropy process) and the low pressure exhaust gas from the turbine is at a very low temperature, sometimes as low as -90 °C or less.

Expansion turbines are very widely used as sources of refrigeration in industrial processes such as the extraction of ethane and natural gas liquids (NGLs) from natural gas,[1] the liquefaction of gases (such as oxygen, nitrogen, helium, argon and krypton)[2][3] and other low-temperature processes.

Applications

Although expansion turbines are very commonly used in low-temperature processes, they are used in many other applications as well. This section discusses one of the low temperature processes as well as some of the other applications.

Extracting hydrocarbon liquids from natural gas

Raw natural gas consists primarily of methane (CH4), the shortest and lightest hydrocarbon molecule, as well as various amounts of heavier hydrocarbon gases such as ethane (C2H6), propane (C3H8), normal butane (n-C4H10), isobutane (i-C4H10), pentanes and even higher molecular weight hydrocarbons. The raw gas also contains various amounts of acid gases such as carbon dioxide (CO2), hydrogen sulfide (H2S) and mercaptans such as methanethiol (CH3SH) and ethanethiol (C2H5SH).

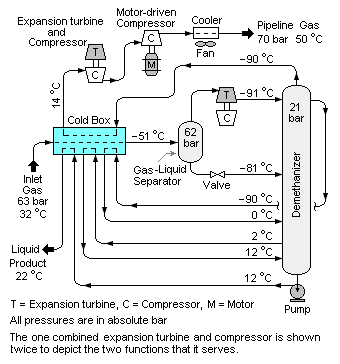

When processed into finished by-products (see Natural gas processing), these heavier hydrocarbons are collectively referred to as NGL (natural gas liquids). The extraction of the NGL often involves an expansion turbine and a low-temperature distillation column (called a demethanizer) as shown in Figure 2. The inlet gas to the demethanizer is first cooled to about −51 °C in a heat exchanger (referred to as a cold box) which partially vaporizes the inlet gas. The resultant gas-liquid mixture is then separated into a gas stream and a liquid stream.

The liquid stream from the gas-liquid separator flows through a valve and undergoes a throttling expansion from an absolute pressure of 62 bar to 21 bar , which is an enthalpic process (i.e., a constant enthalpy process) that results in lowering the temperature of the stream from about −51 °C to about −81 °C as the stream enters the demethanizer.

The gas stream from the gas-liquid separator enters the expansion turbine where it undergoes an isentropic expansion from an absolute pressure of 62 bar to 21 bar that lowers the gas stream temperature from about −51 °C to about −91 °C as it enters the demethanizer to serve as distillation reflux.

Liquid from the top tray of the demethanizer (at about −90 °C) is routed through the cold box where it is warmed to about 0 °C as it cools the inlet gas, and is then returned to the lower section of the demethanizer. Another liquid stream from the lower section of the demethanizer (at about 2 °C) is routed through the cold box and returned to the demethanizer at about 12 °C. In effect, the inlet gas provides the heat required to "reboil" the bottom of the demethanizer and the expansion turbine removes the heat required to provide reflux in the top of the demethanizer.

The overhead gas product from the demethanizer at about −90 °C is processed natural gas that is of suitable quality for distribution to end-use consumers by pipeline. It is routed through the cold box where it is warmed as it cools the inlet gas. It is then compressed in the gas compressor which is driven by the expansion turbine and further compressed in a second-stage gas compressor driven by an electrical motor before entering the distribution pipeline.

The bottom product from the demethanizer is also warmed in the cold box, as it cools the inlet gas, before it leaves the system as NGL.

Power recovery in fluid catalytic cracker

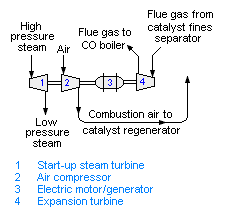

The combustion flue gas from the catalyst regenerator of a fluid catalytic cracker is at a temperature of about 715 °C and at a pressure of about 2.4 barg. Its gaseous components are mostly carbon monoxide (CO), carbon dioxide (CO2) and nitrogen (N2). Although the flue gas has been through two stages of cyclones (located within the regenerator) to remove entrained catalyst fines, it still contains some residual catalyst fines.

Figure 3 depicts how power is recovered and utilized by routing the regenerator flue gas through an expansion turbine. After the flue gas exits the regenerator, it is routed through a secondary catalyst separator containing swirl tubes designed to remove 70 to 90 percent of the residual catalyst fines.[4] This is required to prevent erosion damage to the expansion turbine.

As shown in Figure 3, expansion of the flue gas through an expansion turbine provides sufficient power to drive the regenerator's combustion air compressor. The electrical motor-generator in the power recovery system can consume or produce electrical power. If the expansion of the flue gas does not provide enough power to drive the air compressor, the electric motor-generator provides the needed additional power. If the flue gas expansion provides more power than needed to drive the air compressor, than the electric motor-generator converts the excess power into electric power and exports it to the refinery's electrical system.[5] The steam turbine shown in Figure 3 is used to drive the regenerator's combustion air compressor during start-ups of the fluid catalytic cracker until there is sufficient combustion flue gas to take over that task.

The expanded flue gas is then routed through a steam-generating boiler (referred to as a CO boiler) where the carbon monoxide in the flue gas is burned as fuel to provide steam for use in the refinery.[5]

The flue gas from the CO boiler is processed through an electrostatic precipitator (ESP) to remove residual particulate matter. The ESP removes particulates in the size range of 2 to 20 microns from the flue gas.[5]

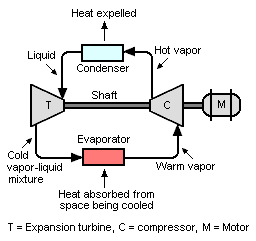

Refrigeration system

Power generation

History

In 1939, Pyotr Kapitza of Russia suggested the use of a centrifugal turbine for the isentropic expansion of gases to produce refrigeration. Since then, centrifugal expansion turbines have taken over almost 100 percent of the gas liquefaction and other low-temperature industrial requirements.

References

- ↑ Demethanzer

- ↑ BOC (NZ) publication: use search function for keyword "expansion"

- ↑ US Department of Energy Hydrogen Program

- ↑ Alex C. Hoffnab and Lewis E. Stein (2002). Gas Cyclones and Swirl Tubes:Principles , Design and Operation, 1st Edition. Springer. ISBN 3-540-43326-0.

- ↑ 5.0 5.1 5.2 Cite error: Invalid

<ref>tag; no text was provided for refs namedReza