Packed bed: Difference between revisions

imported>Milton Beychok m (Fixed credit line in new image) |

mNo edit summary |

||

| (5 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

{{subpages}} | {{subpages}} | ||

[[Image:Koch-Glitsch Cascade Rings.jpg|right|thumb|250px|{{#ifexist:Template:LC Raschig Rings.jpg/credit|{{Koch-Glitsch Cascade Rings.jpg/credit}}<br/>|}}Figure 1: Randomly dumped packing material used in packed beds.]] | [[Image:Koch-Glitsch Cascade Rings.jpg|right|thumb|250px|{{#ifexist:Template:LC Raschig Rings.jpg/credit|{{Koch-Glitsch Cascade Rings.jpg/credit}}<br/>|}}Figure 1: Randomly dumped packing material used in packed beds.]] | ||

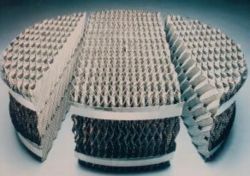

{{Image|Koch-Glitsch Structured Packing.jpg|right|250px|Figure 2: Structured packing material used in packed beds.}} | |||

In [[chemical engineering]] processes such as [[Continuous distillation|distillation]] and [[absorption (chemistry)]], a '''packed bed''' is most usually a zone within a vertical [[pressure vessel]] that is filled with packing material.<ref name=Seader>{{cite book|author=Seader, J.D. and Henley, Ernest J.|title=Separation Process Principles|edition=2nd Edition|publisher=John Wiley & Sons|year=2006|id=ISBN 0-471-46480-5}}</ref><ref name=Kister>{{cite book|author=Kister, Henry Z.|title=[[Distillation Design]]|edition=1st Edition |publisher=McGraw-Hill|year=1992|id=ISBN 0-07-034909-6}}</ref><ref name=King>{{cite book|author=King, C.J.|2nd Edition|title=Separation Processes|publisher=McGraw Hill|year=1980|id=0-07-034612-7}}</ref><ref name=Perry>{{cite book|author=Perry, Robert H. and Green, Don W.|title=[[Perry's Chemical Engineers' Handbook]]|edition=8th Edition| publisher=McGraw-Hill|year=2007|id=ISBN 0-07-142294-3}}</ref> | |||

In [[chemical engineering]] processes such as [[Continuous distillation|distillation]] and [[absorption]], a '''packed bed''' is most usually a zone within a vertical [[pressure vessel]] that is filled with packing material.<ref name=Seader>{{cite book|author=Seader, J.D. and Henley, Ernest J.|title=Separation Process Principles|edition=2nd Edition|publisher=John Wiley & Sons|year=2006|id=ISBN 0-471-46480-5}}</ref><ref name=Kister>{{cite book|author=Kister, Henry Z.|title=[[Distillation Design]]|edition=1st Edition |publisher=McGraw-Hill|year=1992|id=ISBN 0-07-034909-6}}</ref><ref name=King>{{cite book|author=King, C.J.|2nd Edition|title=Separation Processes|publisher=McGraw Hill|year=1980|id=0-07-034612-7}}</ref><ref name=Perry>{{cite book|author=Perry, Robert H. and Green, Don W.|title=[[Perry's Chemical Engineers' Handbook]]|edition=8th Edition| publisher=McGraw-Hill|year=2007|id=ISBN 0-07-142294-3}}</ref> | |||

The packing material may be randomly dumped objects or it may be specially designed structured packing material such as the examples shown in Figures 1 and 2. | The packing material may be randomly dumped objects or it may be specially designed structured packing material such as the examples shown in Figures 1 and 2. | ||

| Line 12: | Line 10: | ||

==Applications== | ==Applications== | ||

In most applications, the purpose of a packed bed is to provide intimate contacting of the upward flowing vapor and the downward flowing liquid in [[separation process|separation processes]] such as distillation and absorption. | |||

In most applications, the purpose of a packed bed is to provide intimate contacting of the upward flowing vapor | |||

In the packed bed, liquids tend to wet the surface of the packing and the vapors pass across this wetted surface, where [[mass transfer]] takes place. Packing material can be used instead of [[Theoretical trays|trays or plates]] to improve separation in distillation columns. Packing offers the advantage of a lower pressure drop across the column when compared to trays or plates, which is especially beneficial when used in [[Vacuum distillation|vacuum distillation]] columns. | In the packed bed, liquids tend to wet the surface of the packing and the vapors pass across this wetted surface, where [[mass transfer]] takes place. Packing material can be used instead of [[Theoretical trays|trays or plates]] to improve separation in distillation columns. Packing offers the advantage of a lower pressure drop across the column when compared to trays or plates, which is especially beneficial when used in [[Vacuum distillation|vacuum distillation]] columns. | ||

| Line 19: | Line 16: | ||

Differently shaped packing materials have different surface areas and different amounts of void space. Both of these factors affect packing performance. In general, the more surface area for a given volume of packing material, the better is the performance of the packing. | Differently shaped packing materials have different surface areas and different amounts of void space. Both of these factors affect packing performance. In general, the more surface area for a given volume of packing material, the better is the performance of the packing. | ||

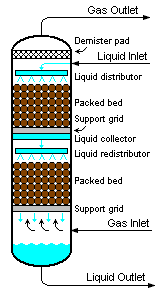

{{Image|Packed Bed Absorption Column.png|right|350px| Figure 3: Schematic diagram of a typical packed bed absorption column.}} | |||

Another factor affecting performance, in addition to packing shape and surface area, is the distribution of vapor and liquid as they that enter the packed bed. The number of [[Theoretical plate|theoretical stages]] required to make a given separation is calculated is a function of the vapor to liquid ratio. If the liquid and vapor are not evenly distributed across the packed bed, the desired separation will not be achieved. The problem is not the packing itself but the mal-distribution of the fluids entering the packed bed. As shown in Figure 3, columns containing packed beds are designed to include liquid distributors so as to distribute the liquid evenly over the cross-sectional area of the packing in order to optimize the efficiency of the mass transfer.<ref name=Seader/><ref name=Kister/><ref name=King/> Methods of evaluating the effectiveness of a liquid distributor can be found in the technical literature.<ref name=Moore>''Random Packing, Vapor and Liquid Distribution: Liquid and gas distribution in commercial packed towers'', Moore, F., Rukovena, F., Chemical Plants & Processing, Edition Europe, August 1987, p. 11-15 </ref><ref name=Spiegel>''Structured Packing, Liquid Distribution: A new method to assess liquid distributor quality'', Spiegel, L., Chemical Engineering and Processing 45 (2006), p. 1011-1017</ref><ref name=Kunesh>''Packed Tower Distributors: Commercial Scale Experiments That Provide Insight on Packed Tower Distributors'', Kunesh, J. G., Lahm, L., Yanagi, T., Ind. Eng. Chem. Res., 1987, vol. 26, p. 1845-1850 [http://www.fri.org Fractionation Research, Inc. (FRI)] (Click on "Publications" and then on "K")</ref> | Another factor affecting performance, in addition to packing shape and surface area, is the distribution of vapor and liquid as they that enter the packed bed. The number of [[Theoretical plate|theoretical stages]] required to make a given separation is calculated is a function of the vapor to liquid ratio. If the liquid and vapor are not evenly distributed across the packed bed, the desired separation will not be achieved. The problem is not the packing itself but the mal-distribution of the fluids entering the packed bed. As shown in Figure 3, columns containing packed beds are designed to include liquid distributors so as to distribute the liquid evenly over the cross-sectional area of the packing in order to optimize the efficiency of the mass transfer.<ref name=Seader/><ref name=Kister/><ref name=King/> Methods of evaluating the effectiveness of a liquid distributor can be found in the technical literature.<ref name=Moore>''Random Packing, Vapor and Liquid Distribution: Liquid and gas distribution in commercial packed towers'', Moore, F., Rukovena, F., Chemical Plants & Processing, Edition Europe, August 1987, p. 11-15 </ref><ref name=Spiegel>''Structured Packing, Liquid Distribution: A new method to assess liquid distributor quality'', Spiegel, L., Chemical Engineering and Processing 45 (2006), p. 1011-1017</ref><ref name=Kunesh>''Packed Tower Distributors: Commercial Scale Experiments That Provide Insight on Packed Tower Distributors'', Kunesh, J. G., Lahm, L., Yanagi, T., Ind. Eng. Chem. Res., 1987, vol. 26, p. 1845-1850 [http://www.fri.org Fractionation Research, Inc. (FRI)] (Click on "Publications" and then on "K")</ref> | ||

| Line 26: | Line 23: | ||

===Other applications=== | ===Other applications=== | ||

Packed beds are also used in certain variants of the distillation and absorption processes referred to as ''[[stripper]]s'' and ''[[scrubber]]s''. | Packed beds are also used in certain variants of the distillation and absorption processes referred to as ''[[stripper]]s'' and ''[[scrubber]]s''. | ||

| Line 34: | Line 30: | ||

==Packed bed process design== | ==Packed bed process design== | ||

There are numerous equations and correlations that have been published in the technical literature for predicting the pressure drop of the vapor traveling through a packed bed and for predicting the height equivalent to a theoretical plate (HETP).<ref name=Kister/><ref name=Perry/> There are also numerous ''rules of thumb'' that have been published for use in the [[process design]] of packed beds and which are simpler to use and probably as accurate as the equations and correlations.<ref name=Kister/> A discussion of all the equations, correlations and rules of thumb would be far beyond the scope of this article. | |||

There are numerous equations and correlations that have been published in the technical literature for predicting the pressure drop of the vapor traveling through a packed bed and for predicting the height equivalent to a theoretical plate (HETP).<ref name=Kister/><ref name=Perry/> There are also numerous ''rules of thumb'' that have been published for use in the process design of packed beds and which are simpler to use and probably as accurate as the equations and correlations.<ref name=Kister/> A discussion of all the equations, correlations and rules of thumb would be far beyond the scope of this article. | |||

The major manufacturers of packing material are other sources of reliable process design information. | The major manufacturers of packing material are other sources of reliable process design information. | ||

== References == | == References == | ||

{{reflist}}[[Category:Suggestion Bot Tag]] | |||

{{reflist}} | |||

Latest revision as of 16:00, 30 September 2024

In chemical engineering processes such as distillation and absorption (chemistry), a packed bed is most usually a zone within a vertical pressure vessel that is filled with packing material.[1][2][3][4]

The packing material may be randomly dumped objects or it may be specially designed structured packing material such as the examples shown in Figures 1 and 2.

The randomly dumped packing may be steel, ceramic or plastic objects of various geometric designs. The structured packing may be sheet metal, woven wire gauze or plastic of various designs and stacked in various arrangements.

Applications

In most applications, the purpose of a packed bed is to provide intimate contacting of the upward flowing vapor and the downward flowing liquid in separation processes such as distillation and absorption.

In the packed bed, liquids tend to wet the surface of the packing and the vapors pass across this wetted surface, where mass transfer takes place. Packing material can be used instead of trays or plates to improve separation in distillation columns. Packing offers the advantage of a lower pressure drop across the column when compared to trays or plates, which is especially beneficial when used in vacuum distillation columns.

Differently shaped packing materials have different surface areas and different amounts of void space. Both of these factors affect packing performance. In general, the more surface area for a given volume of packing material, the better is the performance of the packing.

Another factor affecting performance, in addition to packing shape and surface area, is the distribution of vapor and liquid as they that enter the packed bed. The number of theoretical stages required to make a given separation is calculated is a function of the vapor to liquid ratio. If the liquid and vapor are not evenly distributed across the packed bed, the desired separation will not be achieved. The problem is not the packing itself but the mal-distribution of the fluids entering the packed bed. As shown in Figure 3, columns containing packed beds are designed to include liquid distributors so as to distribute the liquid evenly over the cross-sectional area of the packing in order to optimize the efficiency of the mass transfer.[1][2][3] Methods of evaluating the effectiveness of a liquid distributor can be found in the technical literature.[5][6][7]

Packed columns have a continuous vapor-liquid equilibrium curve, unlike conventional tray distillation in which every tray represents a separate point of vapor-liquid equilibrium. However, when designing packed columns it is useful to first determine the number of theoretical equilibrium stages required for the desired separation. Then the packing height needed to constitute a theoretical equilibrium stage, known as the height equivalent to a theoretical plate (HETP), is also determined. The total packing height required is the number theoretical equilibrium stages multiplied by the HETP.[1][2][3][4]

Other applications

Packed beds are also used in certain variants of the distillation and absorption processes referred to as strippers and scrubbers.

Columns used in certain types of chromatography consisting of a tube filled with packing material are called packed columns and their structure has similarities to packed beds.

Trickle filters used for the biochemical oxidation of sewage and industrial wastewaters employ packed beds referred to as fill or media.

Packed bed process design

There are numerous equations and correlations that have been published in the technical literature for predicting the pressure drop of the vapor traveling through a packed bed and for predicting the height equivalent to a theoretical plate (HETP).[2][4] There are also numerous rules of thumb that have been published for use in the process design of packed beds and which are simpler to use and probably as accurate as the equations and correlations.[2] A discussion of all the equations, correlations and rules of thumb would be far beyond the scope of this article.

The major manufacturers of packing material are other sources of reliable process design information.

References

- ↑ 1.0 1.1 1.2 Seader, J.D. and Henley, Ernest J. (2006). Separation Process Principles, 2nd Edition. John Wiley & Sons. ISBN 0-471-46480-5.

- ↑ 2.0 2.1 2.2 2.3 2.4 Kister, Henry Z. (1992). Distillation Design, 1st Edition. McGraw-Hill. ISBN 0-07-034909-6.

- ↑ 3.0 3.1 3.2 King, C.J. (1980). Separation Processes. McGraw Hill. 0-07-034612-7.

- ↑ 4.0 4.1 4.2 Perry, Robert H. and Green, Don W. (2007). Perry's Chemical Engineers' Handbook, 8th Edition. McGraw-Hill. ISBN 0-07-142294-3.

- ↑ Random Packing, Vapor and Liquid Distribution: Liquid and gas distribution in commercial packed towers, Moore, F., Rukovena, F., Chemical Plants & Processing, Edition Europe, August 1987, p. 11-15

- ↑ Structured Packing, Liquid Distribution: A new method to assess liquid distributor quality, Spiegel, L., Chemical Engineering and Processing 45 (2006), p. 1011-1017

- ↑ Packed Tower Distributors: Commercial Scale Experiments That Provide Insight on Packed Tower Distributors, Kunesh, J. G., Lahm, L., Yanagi, T., Ind. Eng. Chem. Res., 1987, vol. 26, p. 1845-1850 Fractionation Research, Inc. (FRI) (Click on "Publications" and then on "K")