Gunpowder: Difference between revisions

imported>Howard C. Berkowitz |

imported>Howard C. Berkowitz No edit summary |

||

| Line 7: | Line 7: | ||

There are two broad classes of gunpowder, [[#black powder|black]] and [[#smokeless powder|smokeless powder]]. Smokeless powder — a relative term, as it produces some smoke but not dense clouds — has replaced black powder for almost all applications not involving historical reenactment. Modern smokeless powders, of various formulations, are both safer and more powerful than black powder. | There are two broad classes of gunpowder, [[#black powder|black]] and [[#smokeless powder|smokeless powder]]. Smokeless powder — a relative term, as it produces some smoke but not dense clouds — has replaced black powder for almost all applications not involving historical reenactment. Modern smokeless powders, of various formulations, are both safer and more powerful than black powder. | ||

===Black powder=== | ===Black powder=== | ||

Black gunpowder was first developed in [[China]], no later than the eleventh century A.D., and possibly earlier. (Early texts are not clear if the mixture described is true gunpowder or not.) It was introduced into Europe in the thirteenth century, through unknown routes. The earliest known description of a true gunpowder formula is in a letter from [[Francis Bacon]] to [[Pope Clement IV]] in 1267 A.D. By 1275, [[Albertus Magnus]] described a formula of four parts saltpeter to one part charcoal and one part sulfur; the chemically ideal proportions are closer to 75% saltpeter, 11.5% sulfur, and 13.5% charcoal. | Black gunpowder was first developed in [[China]], no later than the eleventh century A.D., and possibly earlier. (Early texts are not clear if the mixture described is true gunpowder or not.) It was introduced into Europe in the thirteenth century, through unknown routes. The earliest known description of a true gunpowder formula is in a letter from [[Francis Bacon]] to [[Pope Clement IV]] in 1267 A.D. By 1275, [[Albertus Magnus]] described a formula of four parts saltpeter ([[potassium nitrate]]) to one part [[charcoal (material)]] and one part [[sulfur]]; the chemically ideal proportions are closer to 75% saltpeter, 11.5% sulfur, and 13.5% charcoal. | ||

The earliest European was a finely ground mixture of charcoal, potassium nitrate, and sulfur. This mixture, known as "serpentine powder," tended to absorb moisture, to separate into its components while being transported, and did not burn if packed too tightly into a gun. It gave way in the 15th century to corned powder which was pressed into pellets and screened to a uniform size. | The earliest European was a finely ground mixture of charcoal, potassium nitrate, and sulfur. This mixture, known as "serpentine powder," tended to absorb moisture, to separate into its components while being transported, and did not burn if packed too tightly into a gun. It gave way in the 15th century to corned powder which was pressed into pellets and screened to a uniform size. | ||

Even with better mechanical formulation, black powder is extremely sensitive to friction and heat, and, while having less explosive power when confined, is far more dangerous to handle than smokeless powder. | Even with better mechanical formulation, black powder is extremely sensitive to friction and heat, and, while having less explosive power when confined, is far more dangerous to handle than smokeless powder. Aside from its use in historical applications, it still has applications as part of the initiating system of [[artillery]] shells. | ||

===Smokeless powder=== | ===Smokeless powder=== | ||

Black powder has gradually been superseded in common use by other propellants which provide higher energy density, lack of smoke, or other desirable properties. In the mid-19th century chemists realized that black-powder smoke wasted fuel, reducing muzzle velocity, while a smokeless powder converted all its fuel, allowing for increased velocity of projectiles. Increased velocity was necessary for rapid-fire shells and in battle against ironclad vessels. In 1884, Frenchman Paul Vieille invented smokeless gunpowder. | Black powder has gradually been superseded in common use by other propellants which provide higher energy density, lack of smoke, or other desirable properties. In the mid-19th century chemists realized that black-powder smoke wasted fuel, reducing muzzle velocity, while a smokeless powder converted all its fuel, allowing for increased velocity of projectiles. Increased velocity was necessary for rapid-fire shells and in battle against ironclad vessels. In 1884, Frenchman Paul Vieille invented smokeless gunpowder. | ||

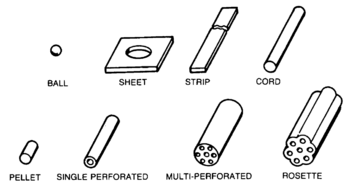

[[Image:Unburnt explosive grain shapes.png|thumb|left|350px|Shapes of unburnt grains]] | |||

Modern smokeless powders are of three basic types: | Modern smokeless powders are of three basic types: | ||

*[[single-base propellant]]: [[Nitrocellulose]] and inert ingredients for mechanical properties | *[[single-base propellant]]: [[Nitrocellulose]] and inert ingredients for mechanical properties | ||

*[[double-base propellant]]: [[Nitrocellulose]], [[nitroglycerin]] or other plasticizer of nitrocellulose, and inert ingredients for mechanical properties | *[[double-base propellant]]: [[Nitrocellulose]], [[nitroglycerin]] or other plasticizer of nitrocellulose, and inert ingredients for mechanical properties | ||

*[[triple-base propellant]]: [[Nitrocellulose]], [[nitroglycerin]] or equivalent, [[nitroguanidine]], and inert ingredients for mechanical properties | *[[triple-base propellant]]: [[Nitrocellulose]], [[nitroglycerin]] or equivalent, [[nitroguanidine]], and inert ingredients for mechanical properties | ||

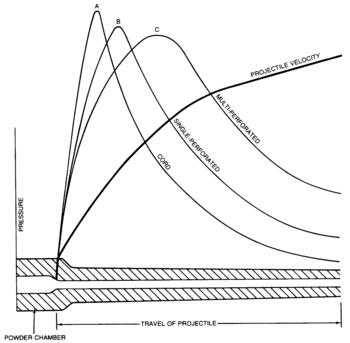

[[Image:Grain-determined pressure vs time.png|right|thumb|350px|Shape-pressure-time relationships]] | |||

After mixing the ingredients, smokeless powder is a plastic material that can be cast, extruded, or otherwise made into specific '''grain''' shapes and sizes. "For example, as a cord burns, the | |||

surface area of exposed propellant decreases. This is | |||

called a degressive grain. "As a single perforated grain | |||

burns, the exposed surface area remains nearly | |||

constant because the outer surface area decreases as | |||

the inner surface area increases. This is called a neutral | |||

grain. In a progressive grain, for example the multiperforated and rosette, the surface area increases | |||

during burning. | |||

The grain geometry and burning rate | |||

are interrelated. The burning time of a propelling charge | |||

that contains a propellant with a high burning rate and | |||

strongly digressive grain geometry could be equal to the | |||

burning time of a charge that contains a propellant with | |||

a low burning rate and strongly progressive grain | |||

geometry. European nations have favored the use of | |||

single perforation, strip, and cord propellants. The | |||

United States uses single perforation and multiperforation | |||

propellants. The single perforation grains | |||

may be slotted or unslotted. The slotted grain has the | |||

desirable characteristic of venting gas during | |||

combustion. All countries use ball propellants for [[small arms]]."<ref name=ExplTM>{{citation | |||

| id = TM 9-1300-214 | |||

| publisher = [[U.S. Department of the Army]] | |||

| date = September 1984 | title = Military Explosives}}, pp. 9-5 to 9-11}}</ref> These affect the burning time and the shape of the pressure-versus-time curve. | |||

Burning time is related to the [[detonation velocity]] (or deflagration velocity) of the material, and the total surface area of propellant exposed. Grain shape affects the area exposed. Complex shapes allow control of the development of pressure. | |||

==Civilian uses== | ==Civilian uses== | ||

| Line 37: | Line 68: | ||

For some time, black powder continued in use as an igniter for the propellant charge, particularly in the larger guns. With later developments, propellants consisting of either nitrocellulose or nitroglycerine were described as "single-base" powder; others containing both were described as "double-base"; and a third category containing nitrocellulose, nitroglycerine, and other chemicals was called "triple-base" or "multiple-base." At the close of the 19th century, the U.S. Navy followed the lead of the French and adopted a nitrocellulose powder as a propellant charge. | For some time, black powder continued in use as an igniter for the propellant charge, particularly in the larger guns. With later developments, propellants consisting of either nitrocellulose or nitroglycerine were described as "single-base" powder; others containing both were described as "double-base"; and a third category containing nitrocellulose, nitroglycerine, and other chemicals was called "triple-base" or "multiple-base." At the close of the 19th century, the U.S. Navy followed the lead of the French and adopted a nitrocellulose powder as a propellant charge. | ||

This proved reasonably satisfactory until World War II night engagements, when smokeless powder was objectionable because its flash temporarily blinded the ships' crews. Various flash suppressors were devised and mixed with the powder, which was formed into grains for small guns and into pellets for the larger guns. The British used a multiple-based powder, Cordite N, which was relatively flash-free, but which the U.S. Navy considered to be brittle, unduly sensitive to shock, and hazardous in hot climates. As a result the United States developed other flashless powders and was placing one of them, Albanite, in large scale production at the end of World War II. | This proved reasonably satisfactory until World War II night engagements, when smokeless powder was objectionable because its flash temporarily blinded the ships' crews. Various flash suppressors were devised and mixed with the powder, which was formed into grains for small guns and into pellets for the larger guns. The British used a multiple-based powder, [[Cordite]] N, which was relatively flash-free, but which the U.S. Navy considered to be brittle, unduly sensitive to shock, and hazardous in hot climates. As a result the United States developed other flashless powders and was placing one of them, Albanite, in large scale production at the end of World War II. [[Triple-base propellant]]s are especially flameless. | ||

Despite the adoption of smokeless powder, black powder still continued in use as a burster charge for projectiles until just before World War I, when more powerful and less sensitive explosives were adopted. In the U.S. Navy, trinitrotoluene ([[TNT]]) was adopted for smaller projectiles and Explosive D (ammonium picrate) for the larger ones. These continued in use throughout World War II, although by the end of the war more powerful explosives had come into use, particularly in the smaller antiaircraft projectiles. If the entire spectra of powder uses is considered--torpedoes, mines, aerial bombs, and rockets, as well as large and small projectiles--the trend in explosive development, beginning with the adoption of smokeless powder, was to recognize the special demands of various uses and to formulate specialized compounds tailor-made to particular requirements. | Despite the adoption of smokeless powder, black powder still continued in use as a burster charge for projectiles until just before World War I, when more powerful and less sensitive explosives were adopted. In the U.S. Navy, trinitrotoluene ([[TNT]]) was adopted for smaller projectiles and [[Explosive D]] (ammonium picrate) for the larger ones. These continued in use throughout World War II, although by the end of the war more powerful explosives had come into use, particularly in the smaller antiaircraft projectiles. If the entire spectra of powder uses is considered--torpedoes, mines, aerial bombs, and rockets, as well as large and small projectiles--the trend in explosive development, beginning with the adoption of smokeless powder, was to recognize the special demands of various uses and to formulate specialized compounds tailor-made to particular requirements. | ||

==References== | ==References== | ||

{{reflist}} | {{reflist|2}} | ||

Revision as of 10:16, 22 April 2010

Gunpowder is a propellant used in firearms, fireworks, and rocket motors. Gunpowder is a low explosive - it burns rapidly without outside air, and in a confined space, will build up enough pressure to cause an explosion. However, it does not detonate in the manner of a high explosive.

History

There are two broad classes of gunpowder, black and smokeless powder. Smokeless powder — a relative term, as it produces some smoke but not dense clouds — has replaced black powder for almost all applications not involving historical reenactment. Modern smokeless powders, of various formulations, are both safer and more powerful than black powder.

Black powder

Black gunpowder was first developed in China, no later than the eleventh century A.D., and possibly earlier. (Early texts are not clear if the mixture described is true gunpowder or not.) It was introduced into Europe in the thirteenth century, through unknown routes. The earliest known description of a true gunpowder formula is in a letter from Francis Bacon to Pope Clement IV in 1267 A.D. By 1275, Albertus Magnus described a formula of four parts saltpeter (potassium nitrate) to one part charcoal (material) and one part sulfur; the chemically ideal proportions are closer to 75% saltpeter, 11.5% sulfur, and 13.5% charcoal.

The earliest European was a finely ground mixture of charcoal, potassium nitrate, and sulfur. This mixture, known as "serpentine powder," tended to absorb moisture, to separate into its components while being transported, and did not burn if packed too tightly into a gun. It gave way in the 15th century to corned powder which was pressed into pellets and screened to a uniform size.

Even with better mechanical formulation, black powder is extremely sensitive to friction and heat, and, while having less explosive power when confined, is far more dangerous to handle than smokeless powder. Aside from its use in historical applications, it still has applications as part of the initiating system of artillery shells.

Smokeless powder

Black powder has gradually been superseded in common use by other propellants which provide higher energy density, lack of smoke, or other desirable properties. In the mid-19th century chemists realized that black-powder smoke wasted fuel, reducing muzzle velocity, while a smokeless powder converted all its fuel, allowing for increased velocity of projectiles. Increased velocity was necessary for rapid-fire shells and in battle against ironclad vessels. In 1884, Frenchman Paul Vieille invented smokeless gunpowder.

Modern smokeless powders are of three basic types:

- single-base propellant: Nitrocellulose and inert ingredients for mechanical properties

- double-base propellant: Nitrocellulose, nitroglycerin or other plasticizer of nitrocellulose, and inert ingredients for mechanical properties

- triple-base propellant: Nitrocellulose, nitroglycerin or equivalent, nitroguanidine, and inert ingredients for mechanical properties

After mixing the ingredients, smokeless powder is a plastic material that can be cast, extruded, or otherwise made into specific grain shapes and sizes. "For example, as a cord burns, the surface area of exposed propellant decreases. This is called a degressive grain. "As a single perforated grain burns, the exposed surface area remains nearly constant because the outer surface area decreases as the inner surface area increases. This is called a neutral grain. In a progressive grain, for example the multiperforated and rosette, the surface area increases during burning.

The grain geometry and burning rate are interrelated. The burning time of a propelling charge that contains a propellant with a high burning rate and strongly digressive grain geometry could be equal to the burning time of a charge that contains a propellant with a low burning rate and strongly progressive grain geometry. European nations have favored the use of single perforation, strip, and cord propellants. The United States uses single perforation and multiperforation propellants. The single perforation grains may be slotted or unslotted. The slotted grain has the desirable characteristic of venting gas during combustion. All countries use ball propellants for small arms."[1] These affect the burning time and the shape of the pressure-versus-time curve.

Burning time is related to the detonation velocity (or deflagration velocity) of the material, and the total surface area of propellant exposed. Grain shape affects the area exposed. Complex shapes allow control of the development of pressure.

Civilian uses

In terms of civilian uses, the technique of gunpowder blasting for mining was first demonstrated by Caspar Weindel at Schemnitz, Lower Hungary in 1627.The practice spread into Harz and Austria in the 1630's, Saxony and Northern Italy in the 1640s and by the 1650s into the Rhineland and Westphalia. It was introduced and developed in Holland and England after the 1660s. It was replaced by dynamite, invented in the late 1860s by Alfred Nobel.

Military Uses

Gunpowder was used as a propellant for rockets, and to propel shot in cannons and Naval guns. During the late 14th and early 15th centuries, Chinese gunpowder technology spread to the whole of Southeast Asia via both the overland and maritime routes, long before the arrival of European firearms. The impact of Chinese firearms on northern mainland Southeast Asia in terms of warfare and territorial expansion was profound.

Land warfare

Sieges were the primary form of warfare in the Middle Ages in Europe. During the period 1346-1500 cannon complemented catapults in siege warfare; only after 1480 did technical improvements in gunpowder and metallurgy render catapults obsolete. Cannons shooting lead, iron or stone projectiles could knock down a castle's high walls, hence the castle had to be abandoned. New fortifications were invented, such as the star shape, such that each wall sloped away from the attacker, reducing the impact of the cannon. One of the main innovators was Italian architect Francesco Di Giorgio, who worked in southern Italy. [2]

Few technological developments in the history of warfare have been as portentous as the appearance around the turn of the 16th century of effective heavy gunpowder ordnance on shipboard, which began a new era in sea warfare. Employed on Mediterranean war galleys and Portuguese caravels, the weapons marked the solution of a series of daunting technological problems, beginning with the appearance of gunpowder in Europe about 1300. Unlike developments on land, change was at first gradual, but shortly after 1400 the pace of development sharply accelerated to culminate in what may legitimately be termed a revolution in firepower at sea.[3]

To obtain maximum effectiveness from the longer barrel on naval guns, the burning rate of the powder needed to be closely controlled. Much experimentation was performed on the effect of size and shape of powder particles on rate of burning, and larger grains were provided for larger guns. Changes in composition were also experimented with, and in the 1880s brown powder made from under-burnt charcoal was adopted as one means of decreasing the burning rate. A serious drawback of these gunpowders was that only about half of the mixture was converted into gas, the remainder becoming a dense smoke. The French in 1886 adopted smokeless powder made of nitrocellulose (gun-cotton). Four years later, the Royal Navy began using smokeless powder made from a nitroglycerine base. Both these compounds liberated four to five times as much energy as did the black powder used earlier. In addition, these materials could be formed readily into grains so shaped as to control the rate of burning. This gave a uniform pressure, permitting a higher projectile velocity without straining the gun.

For some time, black powder continued in use as an igniter for the propellant charge, particularly in the larger guns. With later developments, propellants consisting of either nitrocellulose or nitroglycerine were described as "single-base" powder; others containing both were described as "double-base"; and a third category containing nitrocellulose, nitroglycerine, and other chemicals was called "triple-base" or "multiple-base." At the close of the 19th century, the U.S. Navy followed the lead of the French and adopted a nitrocellulose powder as a propellant charge.

This proved reasonably satisfactory until World War II night engagements, when smokeless powder was objectionable because its flash temporarily blinded the ships' crews. Various flash suppressors were devised and mixed with the powder, which was formed into grains for small guns and into pellets for the larger guns. The British used a multiple-based powder, Cordite N, which was relatively flash-free, but which the U.S. Navy considered to be brittle, unduly sensitive to shock, and hazardous in hot climates. As a result the United States developed other flashless powders and was placing one of them, Albanite, in large scale production at the end of World War II. Triple-base propellants are especially flameless.

Despite the adoption of smokeless powder, black powder still continued in use as a burster charge for projectiles until just before World War I, when more powerful and less sensitive explosives were adopted. In the U.S. Navy, trinitrotoluene (TNT) was adopted for smaller projectiles and Explosive D (ammonium picrate) for the larger ones. These continued in use throughout World War II, although by the end of the war more powerful explosives had come into use, particularly in the smaller antiaircraft projectiles. If the entire spectra of powder uses is considered--torpedoes, mines, aerial bombs, and rockets, as well as large and small projectiles--the trend in explosive development, beginning with the adoption of smokeless powder, was to recognize the special demands of various uses and to formulate specialized compounds tailor-made to particular requirements.

References

- ↑ Military Explosives, U.S. Department of the Army, September 1984, TM 9-1300-214, pp. 9-5 to 9-11}}

- ↑ Michael S. A. Dechert, "The Military Architecture of Francesco Di Giorgio in Southern Italy." Journal of the Society of Architectural Historians 1990 49(2): 161-180. Issn: 0037-9808 Fulltext: in Jstor]

- ↑ Guilmartin, "The Earliest Shipboard Gunpowder Ordnance" (2007)